Waste plastic to diesel fuel plant can convert waste plastic into useful diesel which is comprised by two different machines, one is waste plastic to fuel oil plant, and the other one is plastic oil to diesel plant.

Waste plastic to diesel fuel plant can convert waste plastic into useful diesel which is comprised by two different machines, one is waste plastic to fuel oil plant, and the other one is plastic oil to diesel plant. Generally speaking, there are two main steps to get diesel from waste plastic by waste plastic to diesel fuel plant. Firstly, putting the waste plastic into waste plastic to fuel oil plant where we can get plastic oil. Secondly, refining the plastic oil through the plastic oil to diesel plant, then we can get the final oil-diesel which can be used for tractor, trucks, ships and generator power etc. Here we have a detailed process for you.

Waste plastic to diesel fuel plant

Waste plastic to diesel fuel plant

Getting plastic oil from waste plastic to fuel oil plant:

1.Feeding waste plastic into pyrolysis reactor, start heating, the waste plastics would be pyrolyzed into gas.

2.Condensing the gas by cooling system, the oil gas will be condensed into oil and flow into oil tank ( normally in the 200~300 phase, temperature rised the fastest, and oil comes out the most), and the incondensable gas will be will be recycled to heat the pyrolysis reactor.

3.After verifying the oil gas has been extracted out completely, shut and cool down the machine, two hours later, open the carbon black slagging door to discharge the carbon black.

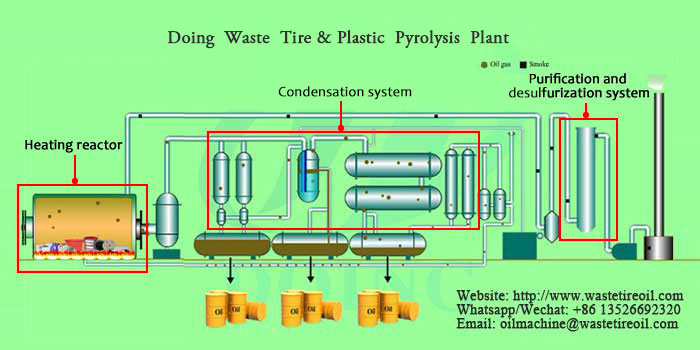

The flow chart of waste plastic to fuel oil plant

The flow chart of waste plastic to fuel oil plant

Getting diesel from plastic oil to diesel plant:

1.Pump waste used oil into distillation reactor, close the reactor door, start heating (indirect heating system makes the distillation fast and efficient and prolong the service life of reactor, the heating material can be wood, natural gas or oil).

2. Collect oil (when the temperature reach around 150 degree , oil gas will come out, then go through the cooling system to liquid into distillation oil).

3. Odor and color removal process. After this process, good quality distillation oil can be obtained.

4. Slagging ( the residue can be discharged easily without waiting the reactor cool down ).

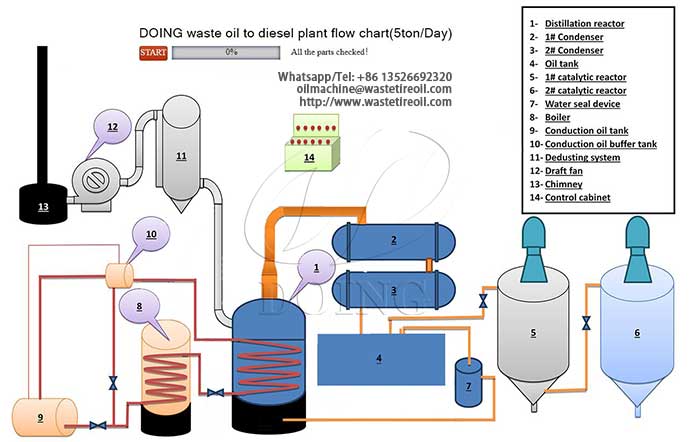

The flow chart of plastic oil to diesel plant

The flow chart of plastic oil to diesel plant

Technical parameter of waste plastic to diesel fuel plant:

| Items Plants | Waste plastic to fuel oil plant | Plastic oil to diesel plant |

| Model | DY-1T, DY-6T,DY-8T,DY-10T... | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | Waste plastic (PP, PE, PS, ABS, Plastic bags, plastic garbage....) | Motor oil, waste tire crude oil, plastic crude oil |

| Structure form | Horizontal rotation | Vertical design with automatical slagging system |

| Heating method | Direct heating | Indirect heating |

| Operating pressure | Normal pressure | Constant pressure |

| Heating material | Fuel oil, LPG, Natural gas, Coal, Wood | Coal, charcoal, fuel gas, fuel oil |

| Average out-put rate | Different types of plastic have different oil yield, generally is around 60% | 85% |

| Material of reactor | 4 different materials of reactor | 4 different materials of reactor |

| Thickness of reactor | 14mm/16mm/18mm | 16mm |

| Mode of cooling | Circulating waster cooling | Recycled water cooling |

| Power in total | 15kw | 20 Kw |

| Service life | Average 6 years | average 7 years |

| Land area | 500㎡ | 180㎡ |

Main features of waste plastic to diesel fuel plant:

1.Efficient

Through the waste plastic to diesel fuel plant, you can get not only diesel from plastic, but also carbon black and asphalt at one time.

2.Energy saving

You can get incondensable gas from waste plastic to fuel oil pant which also can be reused as heating material for pyrolysis reactor, and the fast heating system of plastic oil to diesel plant can keep temperature even after slagging so that you can use for next batch.

3. Safe

Strict quality control system and professional safety devices guarantee our pyrolysis oil to diesel plant running safely and win a good reputation from customers.

4. Environmental friendly

Professional dedusting systems ensure our pyrolysis oil to diesel plant runs zero pollution.

Through the combined action of waste plastic pyrolysis plant and plastic pyrolysis oil to diesel plant can realize the conversion from waste plastic to diesel oil, making profit from "white pollution". For more information about waste plastic to diesel fuel plant, please feel free to contact us and we will provide you with professional advice and solutions.

Waste Plastic Pyrolysis Plant Flow Chart

Converting Plastic Oil to Diesel Flow Chart

Copyright © 2015-2025.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.