Phone: +86-371-5677-1821

TEL : +86-135-2669-2320

Email: sales@wastetireoil.com

Whatsapp:+86-135-2669-2320

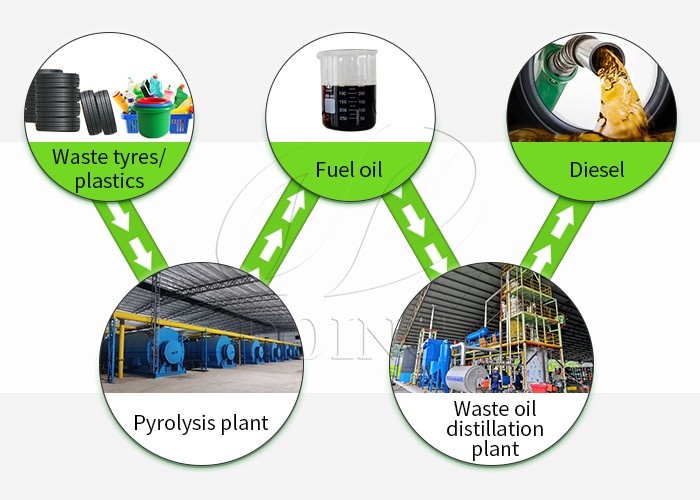

As the polymeric organic compounds, when the waste tire plastic is heated in the anaerobic environment, they will be pyrolyzed into small molecules. After cooling, these small molecules will re-combine to form liquid hydrocarbons and gaseous hydrocarbons. After distillation, we can get diesel from them.

DOING Company focused on the research and development of pyrolysis and distillation machines for 12 years, so our company has a mature and complete pyrolysis and distillation process. Next DOING Company can show you the detailed process about how to convert tire plastic to diesel with the pyrolysis machines and distillation machines.

Pyrolysis machines and distillation machines convert waste tire plastic to diesel

Pyrolysis machines and distillation machines convert waste tire plastic to diesel

1. Put the waste plastics/tires into the reactor of the pyrolysis machine, and heat the reactor. When it is heated to a certain temperature, the plastics/tires will be cracked to generate oil gas.

2. The oil gases are cooled into oil through the multi-stage cooling system. After passing through the cooling system, almost all the oil gas will be recovered. Then we can recycle plastic/tire into fuel oil.

3. Put the fuel oil into the distillation reactor of waste oil distillation machine with oil pump and fill the heat conduction oil with the whole heating system.

4. The heating system works to heat fuel oil and the fuel oil will be distillated.

5. The generated oil gas will be catalyzed and then passes through the cooling system to condense into pure distillation oil.

6. Then oil goes into the decoloration system for decoloring with white clay.

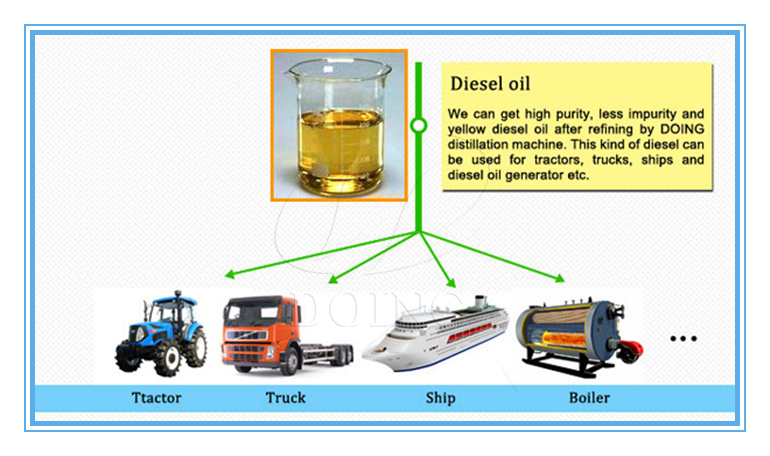

7. Finally, we can recycle fuel oil into diesel, which can be used for heavy machinery, generator and boiler heating.

Waste plastic tire to diesel recyling process

Waste plastic tire to diesel recyling process

In addition to diesel, we can also get other products during the waste tire plastic to diesel recycling process. They all have various usages. When we recycle waste tire plastic to fuel oil, we can also get carbon black which can be briquetted for burning or refined to make new tires, shoe soles or paints. And if the raw material is waste tires, we can also get steel wires, which can be sold as scrap or remelt for other purposes. When we recycle fuel oil to diesel, we can get asphalt for paving or refining.

Various usages of diesel oil recycled from waste tire plastic

Various usages of diesel oil recycled from waste tire plastic

Obviously, the waste tire plastic to diesel recycling process is not so complicated, but during the waste tire plastic to diesel recycling process, we need to pay attention to the following two points:

1. During the process of converting waste tire plastic to fuel oil, if using the continuous pyrolysis machine, the waste tires need to be processed to rubber powder before feeding.

2. In general, we won't combine the waste plastics and tires together when heating because their melting points are different and the oil produced by tires and plastics is of different quality.

So if you are interested in recycling waste tire plastic to diesel or want to learn more about the pyrolysis and distillation machine, please contact us, our technical team can customize the most suitable purchasing schemes according to the place and scale of your project, the raw material processing scale and other aspects.

Releate article:

Copyright © 2015-2026.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.