Continuous waste plastic pyrolysis plant exists for converting waste plastic to fuel oil and carbon black through pyrolysis technology. The machine subjects the waste plastics to very high temperatures and oxygen-free conditions to produce the two product

Continuous waste plastic pyrolysis plant exists for converting waste plastic to fuel oil and carbon black through pyrolysis technology. The machine subjects the waste plastics to very high temperatures and oxygen-free conditions to produce the two products. Furthermore, this continuous waste plastic pyrolysis plant helps eliminate pollution. In addition, you will actually get profits while reducing environmental pollution.

Continuous waste plastic pyrolysis plant

Continuous waste plastic pyrolysis plant

Main Configuration of DOING Continuous Waste Plastic Pyrolysis Plant:

DOING continuous waste plastic pyrolysis plant is mainly composed of pyrolysis reactor, oil tank, horizontal condenser, vertical condenser, buffer chamber, negative pressure chamber, desulfurization & dedusting tower, slagging screw conveyor, square/round carbon black box, circulating water pump, vacuum pump, etc. All of parts are manufactured with high-quality materials and advanced technologies, so the quality of this plant can be guaranteed.

Working Process of Continuous Waste Plastic Pyrolysis Plant

1. Feeding raw materials automatically

Waste plastics are fed into the pyrolysis reactor by the continuous feeding system automatically.

2. Pyrolysis

Heat the reactor and when the waste plastics reach a certain temperature, they will be cracked to generate oil and gas.

3. Condensing

The oil gas coming out from the reactor goes through continuous cooling system, and becomes liquid oil into oil tank. We adopt new-type condenser which can improve the oil yield efficiency and make the oil yield to the maximum.

4. Waste gas recovery

The uncondensable gas can be recycled to heat the reactor as fuel, saving energy and reduce fuel costs for customers. The exhaust gas produced by the combustion is treated by the dust removal and deodorization system, which meets the environmental protection standards and will not cause pollution to the environment.

5. Discharge

The carbon black is discharged automatically. And it can be cooled during the process to a temperature at which we can directly pack and collect, saving cooling time and increasing productivity.

Product and Application:

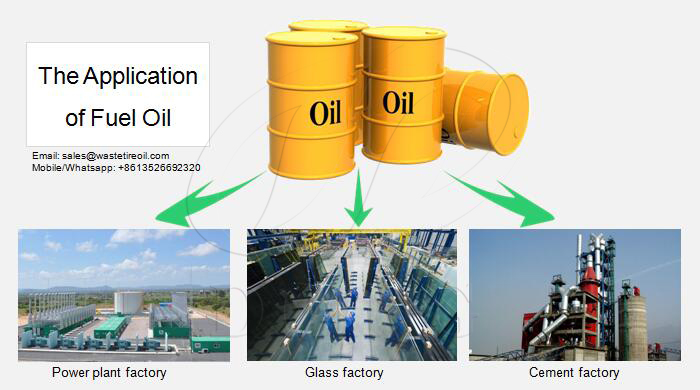

The carbon black could be made into pellets for burning and heating , just like coal, or refining for making new rubber products. And the fuel oil is a good heating fuel wide used for industrial and commercial purposes, such as power plant factory, glass factory, cement factory, etc.

Fuel oil application

Fuel oil application

Main Advantages of Continuous Waste Plastic Pyrolysis Plant:

DOING continuous waste plastic pyrolysis plant is improved and designed on the basis of batch type waste plastic pyrolysis plant. Compared with traditional operating systems, the continuous waste plastic pyrolysis plant mainly has many improvements:

1. Continuous waste plastic pyrolysis plant is equipped with accurate calculated pyrolysis system , which can monitor the cracking of the plastic in the reactor in real time and automatically adjust to ensure adequate pyrolysis of the plastic to get high oil output.

2. The continuous waste plastic pyrolysis plant can run 24 hours a day, no need to stop.

3. The continuous waste plastic pyrolysis plant is fully automatic and controlled by has high degree of automation, easy to operate so saving labor. It has continuous feeding and slagging system, PLC control system, which need only 1-2 worker to operate, saving labor cost.

4. Unique sealing design of both feeding and slagging system is designed to prevent the smoke and dust from entering the air to guarantee for safety guarantee and environment protection.

5. Continuous waste plastic pyrolysis plant can more waste plastic. DOING supplies 10TPD, 20TPD, 30TPD. 50TPD continuous waste plastic pyrolysis plant for you to choose.

6. The continuous waste plastic pyrolysis plant can not only dispose waste plastics, but also deal with many other kinds of waste materials, such as tyre, rubber, oil sludge, coal tar, etc.

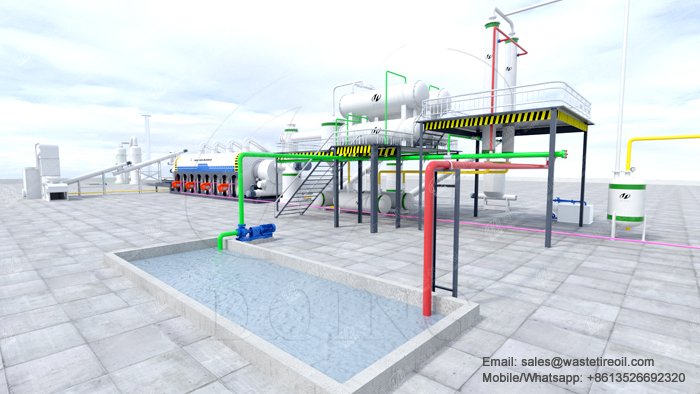

3D drawing of continuous waste plastic pyrolysis plant

3D drawing of continuous waste plastic pyrolysis plant

Up to now, DOING continuous waste plastic pyrolysis plant has been exported to many countries, including Mexico, Nigeria, Egypt, Ukraine, Turkey etc. We have received wide praise from all of our customers. In order to better serve our customers, DOING Company is planning to establish overseas warehouses in Nigeria. In this way, we will delivery faster, provide closer and better after-sale service for customers. Send your inquiry now!

Waste Plastic Pyrolysis Plant Flow Chart

Converting Plastic Oil to Diesel Flow Chart

Copyright © 2015-2026.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.