Phone: +86-371-5677-1821

TEL : +86-135-2669-2320

Email: sales@wastetireoil.com

Whatsapp:+86-135-2669-2320

In November 2025, DOING successfully shipped a 10TPD batch plastic pyrolysis machine to Indonesia. The client, an Indonesian waste recycling enterprise, plans to use this equipment to convert waste plastic into fuel oil for its own factory's operations, achieving resource reuse while reducing fuel procurement costs.

The cooperation originated in August 2025 when the Indonesian client initiated an inquiry, clearly stating the demand for high-quality and cost-effective plastic pyrolysis equipment. DOING business manager responded promptly and provided detailed product information and solutions tailored to the client's actual needs. Impressed by the professional and attentive service, the client visited to DOING manufacturing facility shortly after. During the inspection, they closely examined the production process, quality control system and sample equipment of the 10TPD batch plastic pyrolysis machine, and expressed full satisfaction with the equipment's quality and the factory's production strength. Subsequently, the client formally placed an order with DOING.

The shipped 10TPD batch plastic pyrolysis machine is customized to meet the Indonesian client's operational requirements, with core components and systems including:

Shipment of DOING batch plastic pyrolysis reactor to Indonesia

Shipment of DOING batch plastic pyrolysis reactor to Indonesia

10TPD batch plastic pyrolysis reactor: Made of customized national standard Q345R material, which features high temperature resistance and corrosion resistance. It adopts a side slag discharge method to effectively improve slag discharge speed and reduce operational downtime.

Blower cooler: Ensures efficient cooling of pyrolysis products, improving the yield and quality of pyrolysis oil.

300,000 kcal heavy oil burner: Provides stable heating energy for the pyrolysis reaction, ensuring the smooth progress of the process.

Vacuum negative pressure device: As a key safety component, it maintains the stability of the internal pressure of the reactor and guarantees the overall operational safety of the plastic pyrolysis equipment.

Exhaust gas deodorization system: Effectively removes odors and harmful substances in the exhaust gas, ensuring that the exhaust gas meets Indonesian environmental protection standards and realizes compliant emission.

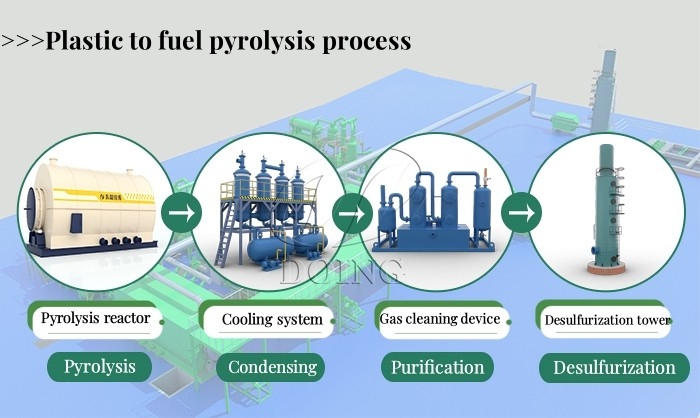

DOING waste plastic recycling machine process

DOING waste plastic recycling machine process

Upon arrival in Indonesia, DOING will provide comprehensive installation services for the pyrolysis machine. The team will ensure the equipment is set up correctly and running smoothly. Stay tuned for future updates as DOING continues to support the project through its installation and operational phases.

Releate article:

Copyright © 2015-2026.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.