Phone: +86-371-5677-1821

TEL : +86-135-2669-2320

Email: sales@wastetireoil.com

Whatsapp:+86-135-2669-2320

From lightweight shopping bags to sturdy packaging boxes, plastic, with its excellent performance and extremely low cost, has long been deeply integrated into our daily lives. However, behind this convenience lies a growing global environmental crisis—"white pollution." The fact that plastic takes hundreds of years to slowly degrade means that every plastic product we manufacture could become a heavy burden for the future. Microplastics, like ghosts, silently infiltrate our food chain, threatening human health.

White pollution-waste plastic

Landfill Overload: Hundreds of millions of tons of plastic waste end up in landfills every year, occupying precious land resources.

Soil Pollution: Plastic releases harmful chemicals during degradation, which seep into soil and groundwater, causing long-term impacts on ecosystems and human health.

Marine Ecosystem Damage: Large amounts of plastic waste enter the ocean, becoming a "killer" of marine life. Sea turtles, seabirds, whales, and other animals often suffer from digestive blockages, malnutrition, and even death due to ingesting plastic. They are also easily entangled in plastic bags, fishing nets, etc., restricting their movement and ultimately making survival difficult.

The Invisible Threat of Microplastics: Under the influence of light and physical abrasion, plastics decompose into tiny plastic particles. These microplastics are widely present in the air, water, soil, and even our food and drinking water. Their long-term effects on human health are still unclear, but they have attracted widespread attention from the global scientific community.

Visual Pollution and Landscape Destruction: Carelessly discarded plastic waste damages natural scenery and urban landscapes, seriously affecting people's quality of life and the development of tourism.

Faced with the serious "white pollution" problem caused by waste plastics, traditional treatment methods such as landfill and simple incineration are inadequate and may even cause secondary pollution. To fundamentally solve this problem, we urgently need more innovative, economical, and environmentally friendly solutions.

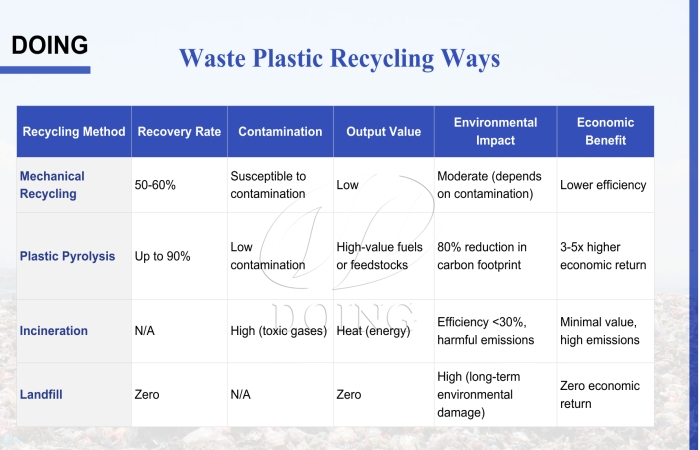

Comparison of waste plastic recycling methods

Waste plastic pyrolysis technology is a highly efficient resource recovery method. It involves heating waste plastics at high temperatures under anaerobic conditions, breaking down their large molecular structure into smaller molecules. The key to this process is "anaerobic pyrolysis," which effectively avoids the production of highly toxic and harmful gases such as dioxins, while simultaneously converting waste plastics into valuable products such as pyrolysis oil and carbon black.

Plastic pyrolysis technology can significantly solve the problem of "white pollution" from waste plastics and brings multiple advantages in terms of environmental protection and the economy:

1. Environmental Benefits

1. Reduced pressure on landfills and incineration: Pyrolysis recycling of waste plastics can significantly reduce the amount of plastic waste entering landfills, alleviating pressure on land resources, while avoiding the harmful gases and fly ash that may be produced by traditional incineration.

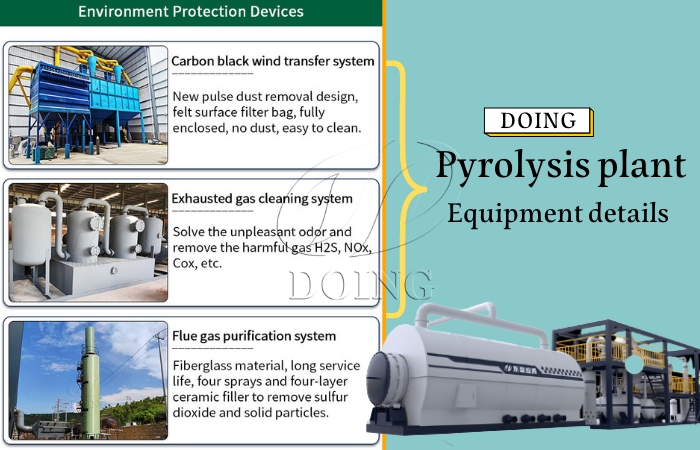

2. Environmental benefits of the pyrolysis plant itself:

1) Waste gas treatment system: The pyrolysis plant is equipped with an advanced waste gas treatment system, including dust removal, condensation, and acid gas neutralization, ensuring that emissions meet national or international environmental standards and eliminating dust, particulate matter, and odors.

DOING waste plastic pyrolysis plant environment protection devices

2) Energy Recovery and Recycling: The cleaned syngas can not only be used as fuel itself, reducing external fuel consumption and greenhouse gas emissions, but more importantly, it prevents potentially harmful gases from being directly released into the atmosphere.

3) Prevention of Dioxin and Other Toxic Substance Formation: The entire pyrolysis process is carried out in a precisely controlled anaerobic environment, effectively avoiding the risk of producing highly toxic substances such as dioxins due to incomplete combustion.

4)Leakage Prevention: From the input of waste plastics and pyrolysis to the output of products, the entire system adopts a fully enclosed design. This prevents plastic fragments, incompletely treated materials, or dust from leaking into the environment during production.

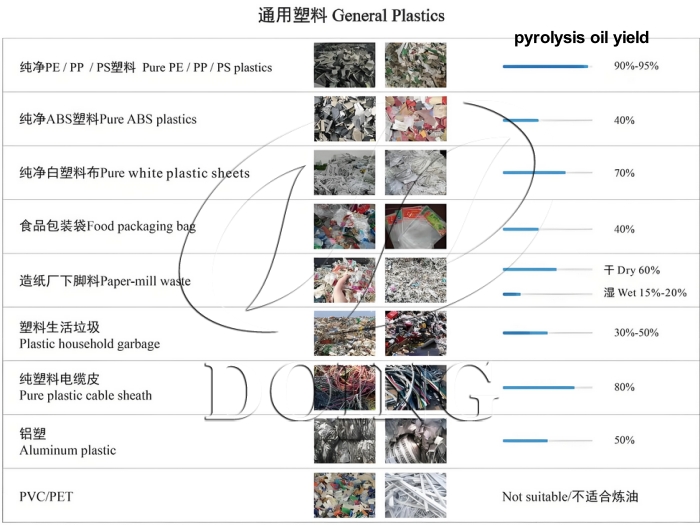

5) Wide Range of Raw Materials: The pyrolysis process can process various plastics, including those that pose health risks due to chemical leaching. It can safely decompose them without producing residue.

Plastic pyrolysis raw materials and oil yield

2. Economic Benefits

Plastic pyrolysis technology not only solves the problem of "what to do" with waste plastics, but more importantly, it transforms useless waste into high-value-added recycled resources, bringing economic returns to investors:

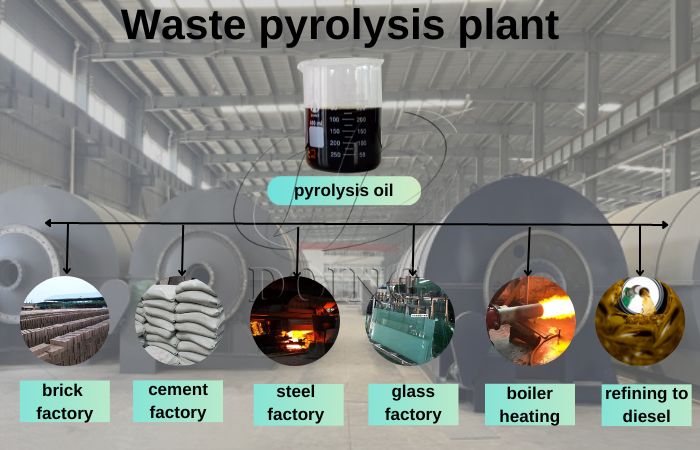

Pyrolysis Oil: The main product after pyrolysis of waste plastics is pyrolysis oil. This oilis similar to crude oil and can be used directly as industrial fuel, widely applied in cement kilns, glass kilns, and steel plant boilers. It can effectively replace traditional fuels such as coal, diesel, and heavy oil, significantly reducing the operating costs of industrial enterprises. Pyrolysis oil can also be refined and used as a substitute for diesel, or for power generation and large machinery fuel.

Applications of pyrolysis oil

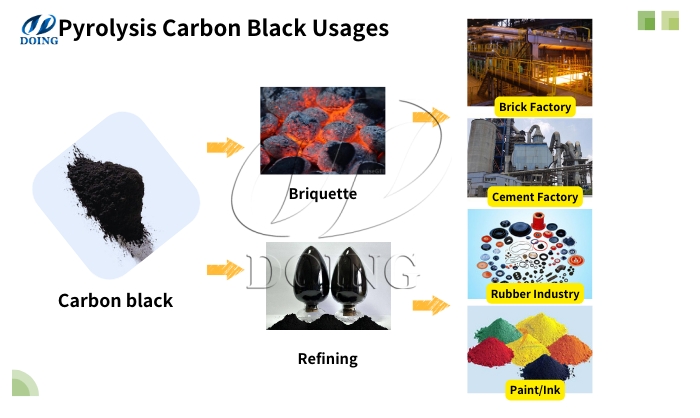

Carbon Black: Carbon black produced during the pyrolysis process is an important raw material for industries such as tires, rubber products, inks, and coatings.

Usages of pyrolysis carbon black

Syngas: Syngas produced during the pyrolysis process, after being cleaned and purified, is directly reused to heat the reactor, forming a closed-loop energy system and greatly reducing external energy consumption during the production process.

DOING pyrolysis plant syngas recycling system

In summary, waste plastic pyrolysis technology provides a pollution control path that combines environmental compliance with economic feasibility by transforming "white pollution" into resources such as pyrolysis oil and carbon black.

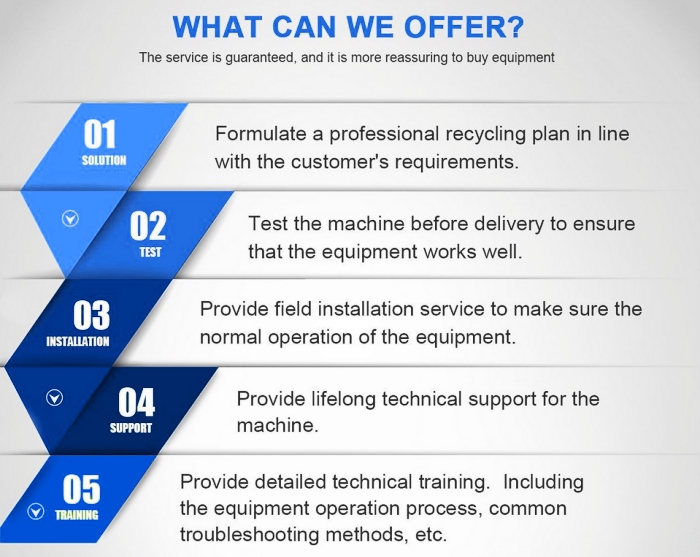

DOING Company has over ten years of professional experience in solid waste pyrolysis treatment, specializing in the technological research and development and manufacturing of pyrolysis plants for plastics and tires. We understand our clients' needs and can not only provide efficient and stable pyrolysis plants but also offer customized plant design solutions based on your specific raw material and capacity requirements. From project consultation, site planning, installation and commissioning to operation training and after-sales support, the DOING team provides a full-service, one-stop solution to ensure your project goes into production smoothly.

DOING waste plastic pyrolysis plant manufacturer

If you are interested in the field of white pollution control or wish to invest in waste plastic resource recovery pyrolysis projects, please feel free to contact us. DOING Company will use its professional technology and reliable products to help you succeed in this industry that combines environmental protection and economic benefits.

Releate article:

Copyright © 2015-2025.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.