Phone: +86-371-5677-1821

TEL : +86-135-2669-2320

Email: sales@wastetireoil.com

Whatsapp:+86-135-2669-2320

Pyrolysis, a method of converting waste into valuable fuel, has gained popularity due to its potential to save energy. But is pyrolysis self-sustaining to save energy? The answer is yes, but it depends on a two-stage energy cycle—start-up preheating and long-term operation. Unlike processes relying on continuous external energy, pyrolysis recovers more of the energy inherent in the waste itself, minimizing energy consumption by minimizing energy expenditure.

DOING waste pyrolysis equipment further enhances this self-sustaining through optimized design, making it a cost-effective and energy-efficient waste-to-fuel recovery solution.

Pyrolytically recoverable raw materials

Pyrolytically recoverable raw materials

Start-up Phase (Energy Consumer):

Before pyrolysis process begin, the waste pyrolysis reactor must reach a temperature typically between 280°C and 450°C depending on the type of waste material. At this stage, the system does not yet generate combustible gases, so external heating is required. The most common fuels used during preheating are:

1.Liquid fuels: Diesel or heavy oil (ideal for small to medium-scale pyrolysis equipment).

2.Solid fuels: Wood, coal, or biomass pellets (cost-effective for regions with abundant biomass resources).

3.Gaseous fuels: Natural gas or LPG (clean-burning, suitable for areas with accessible gas supply).

The preheating phase typically lasts 1–3 hours, depending on the equipment size and fuel type, with minimal energy input compared to the overall operation.

Heavy oil burner of DOING pyrolysis machine

Heavy oil burner of DOING pyrolysis machine

Operational Phase (Energy Producer/Self-Sustaining):

Once the pyrolysis reactor reaches the desired temperature, the raw materials (e.g., tyre, waste plastic, rubber, oil sludge aluminum-plastic composites, etc.) begin to decompose. 5%–10% of the waste is converted into non-condensable pyrolysis gas. This byproduct, syngas, has a high calorific value (30–40 MJ/m³), similar to natural gas, and becomes the primary fuel source for continued operation.

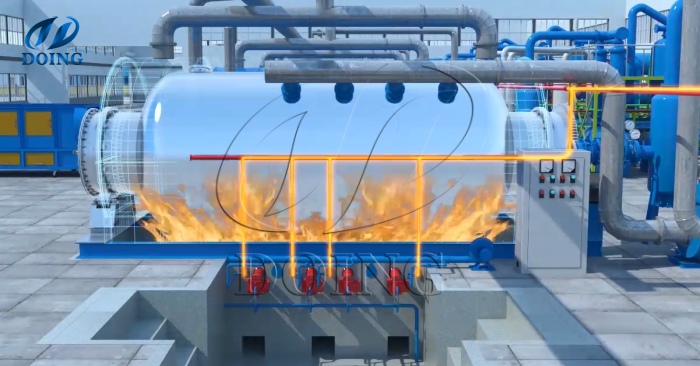

Combustible gas recovery heating pyrolysis reactor

Combustible gas recovery heating pyrolysis reactor

Self-sustaining occurs because the syngas produced during pyrolysis can be used to heat the pyrolysis furnace, minimizing the need for external energy inputs once the system reaches operating temperature. While pyrolysis can be self-sustaining once it reaches operating temperature, several factors can affect how efficiently the system operates.

Factors affecting self-sustaining performance

1.Feedstock Quality: Dry, well-processed feedstocks generate more syngas, while wet or high-moisture materials require more external energy to reach the necessary temperature.

2.Reactor Insulation: Effective insulation minimizes heat loss and helps the system maintain temperature without extra fuel consumption.

3.Gas Quality: Cleaner gases result in more efficient and safer combustion, making energy use more effective.

4.System Design: The type of pyrolysis reactor, whether continuous or batch, affects how effectively energy is utilized.

DOING waste pyrolysis machine design

DOING waste pyrolysis machine design

DOING waste pyrolysis machines are designed with these factors in mind to ensure maximum energy efficiency. Their systems are engineered for optimal heat retention, reducing reliance on external fuel and improving long-term energy savings.

DOING Waste Pyrolysis Equipment: Optimized for Self-Sufficiency

1. Syngas Recycling System: After pyrolysis, the non-condensable gas is cleaned by DOING exhuast gas purification system and reused to heat the reactor. This closed-loop system minimizes fuel consumption during the operating phase.

2. Advanced Insulation: High-quality insulation layers (Four-layer composite insulation material design) ensur that the pyrolysis reactor retains heat, reducing the need for additional heating sources.

3. Efficient Furnace Design: The furnace is optimized to improve heat transfer and reduce energy loss. It adopts a crack-resistant, fully enclosed head design, equipped with corresponding dynamic sealing methods for different material feeding and slag discharge conditions. Furthermore, the reactor sealing design incorporates specialized sealing materials, which allows the system to maintain temperature consistently and efficiently.

4. Flexible Heating Fuel Options: If syngas alone is insufficient to meet heating requirements, the resulting pyrolysis oil can be used as auxiliary fuel.

5. Continuous and Batch Models: DOING offers both continuous and batch pyrolysis machines, allowing customers to select the best system for their operational needs. Continuous pyrolysis machines are more effective at maintaining temperature consistency over long periods.

DOING waste pyrolysis machine types

DOING waste pyrolysis machine types

Generally speaking, pyrolysis is a prime example of a circular economy process. It is designed to be thermally self-sustaining, transforming waste materials into valuable energy products. DOING waste-to-fuel pyrolysis machines are designed to make this process as energy-efficient as possible. If you are interested in learning more about how DOING pyrolysis machines can save energy and improve the efficiency of your operations, feel free to contact us for a consultation.

Releate article:

Copyright © 2015-2025.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.