Phone: +86-371-5677-1821

TEL : +86-135-2669-2320

Email: sales@wastetireoil.com

Whatsapp:+86-135-2669-2320

Pyrolysis technology is a popular waste treatment solution, capable of converting waste into valuable recovered products like pyrolysis oil and carbon black, providing a solution that balances environmental protection and economic benefits for many countries. So, is starting a pyrolysis plant in Indonesia equally applicable and feasible? The answer is undoubtedly yes.

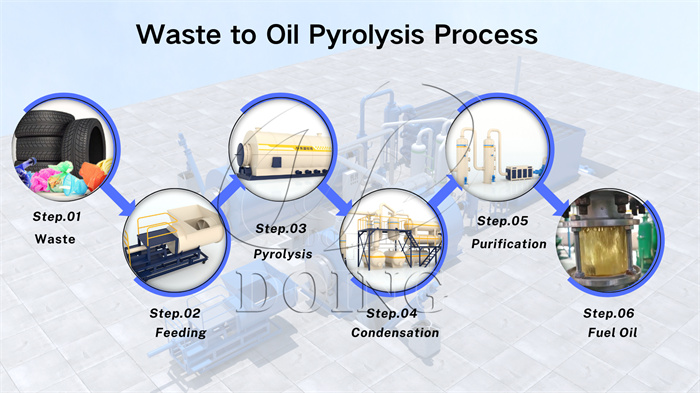

DOING pyrolysis plant working process

Keep reading about our feaibilty study, you mill have a better understanding of pyrolysis industry situation and market potential in Indonesia.

The rise of Indonesia's waste pyrolysis industry is an inevitable result of the combined effects of its severe waste crisis, urgent energy needs, shifting national policies, and environmental trends. This provides the most fundamental "raw material" basis for pyrolysis technology.

1) Huge and continuously growing volume: As the world's fourth most populous country and Southeast Asia's largest economy, Indonesia generates millions of tons of municipal solid waste annually. With urbanization, rising consumption levels, and the development of e-commerce, the amount of waste is growing at an alarming rate, overwhelming existing landfills.

2) The dilemma of waste disposal:

Waste tires: Vast quantities of waste tires accumulate, not only occupying land but also serving as breeding grounds for diseases such as dengue fever. Illegal burning produces highly toxic dioxins and black smoke, causing severe air pollution.

Mixed plastics: Especially low-value, contaminated plastic packaging (such as snack bags), these materials cannot be processed by traditional recycling systems and ultimately end up in the environment or landfills.

Other organic wastes: Such as oil sludge and agricultural waste, can also cause soil and water pollution if not properly disposed of.

In Indonesia, incineration or landfill disposal of waste is prohibited. Local governments encourage people to handle waste in an environmentally friendly way, which provided an opportunity for the establishment of this pyrolysis project.

The economic viability of a pyrolysis plant is directly linked to the market demand for its end products. Pyrolysis technology, when adapted to various organic waste streams, yields a diverse portfolio of valuable outputs:

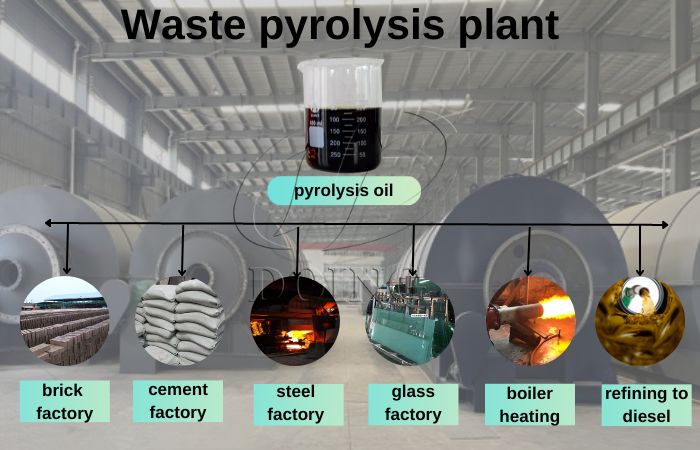

1) Pyrolysis Oil: A primary output, this fuel oil is in high demand across numerous Indonesian industries, including cement manufacturing, glass production, steel mills, power generation, and various boiler facilities. Its utility as an industrial heating fuel offers a cost-effective alternative to conventional fossil fuels. Further refining can yield products akin to diesel, suitable for generators and heavy machinery.

Applications of pyrolysis oil

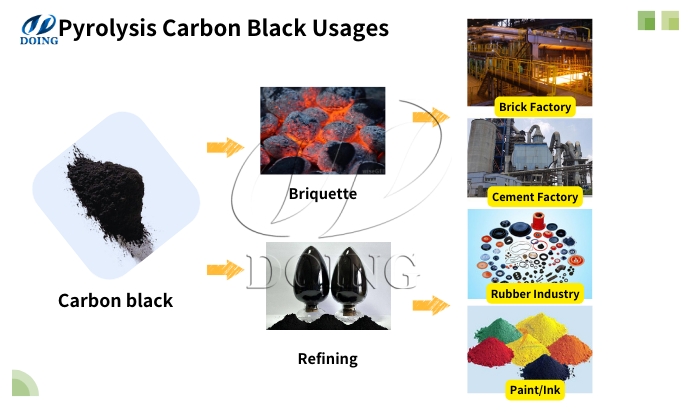

2) Carbon Black: This versatile by-product finds applications in multiple industries. It can be used directly as a fuel, processed into briquettes for energy generation, or refined for use as a reinforcing filler in the rubber industry (e.g., for tire manufacturing, hoses, belts). Its properties also make it valuable as a pigment in paints and inks.

Applications of pyrolysis carbon black

3) Syngas: The non-condensable gases produced during pyrolysis are a significant asset, primarily for on-site energy generation. This gas can efficiently fuel the pyrolysis process itself, dramatically reducing operational energy costs.

DOING pyrolysis plant syngas recycling system

4) Other Recovered Materials: Depending on the feedstock, additional valuable materials like steel wire (from tires) can be recovered and sold as scrap metal, further enhancing the economic output.

In Indonesia, the key to successfully startup a pyrolysis plant lies in comprehensive planning of land and infrastructure.

Key Considerations:

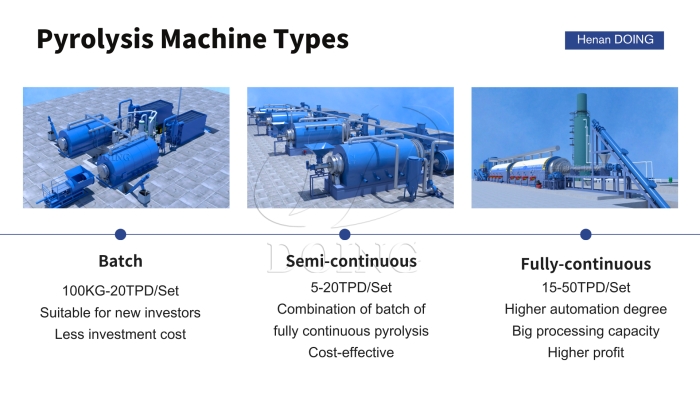

Scale: Land requirements depend on the plant size, type of pyrolysis equipment (batch, semi-continuous, continuous), and waste volume. For example, processing large quantities of waste tires requires a larger site than processing specific types of plastic waste. The required processing area area must be accurately assessed based on the selected technology and processing capacity.

DOING pyrolysis plant types

Storage Capacity: In many parts of Indonesia, especially in industrially concentrated provinces, waste sources can be scattered. Therefore, the site needs sufficient space for incoming material storage to ensure stable production, and provisions for finished product storage to facilitate collection and transportation.

Site Selection: Proximity to waste collection points (such as auto repair shops, industrial zones) can significantly reduce raw material transportation costs. Simultaneously, proximity to major transportation networks (roads, ports) is crucial for the efficient and economical delivery of finished products (fuel oil, carbon black) to the domestic market or for export.

Land planning: Land use planning and industrial land approval vary across Indonesian provinces. Choosing industrial zones or government-planned development areas usually makes it easier to obtain land use and construction approvals, ensuring compliance with local environmental and safety regulations and mitigating compliance risks from improper site selection later on.

Choosing a suitable pyrolysis plant is fundamental to the feasibility of any pyrolysis operation in Indonesia. This not only affects production efficiency and product quality but also directly impacts return on investment and environmental compliance. Indonesia's industrialization and growing waste management needs provide ample market and practical opportunities for selecting appropriate pyrolysis technologies and equipment.

Key Considerations:

Technological Diversity and Adaptability: Indonesia possesses abundant organic waste resources, including waste tires, various plastics, and agricultural residues. Therefore, selecting a pyrolysis plant capable of processing diverse raw materials, or one that can be optimized for different materials, is crucial. DOING pyrolysis plants can process diverse raw materials, such as waste tires, rubber, plastics, sludge, aluminum-plastic composites, medical waste, municipal solid waste, and fiberglass.

DOING pyrolysis plant raw materials

Equipment Performance and Output Quality: The key to evaluating a pyrolysis plant lies in its pyrolysis efficiency and the yield and quality of target products (such as fuel oil, carbon black, and syngas). High-quality products command higher market prices, thereby enhancing the project's profitability.

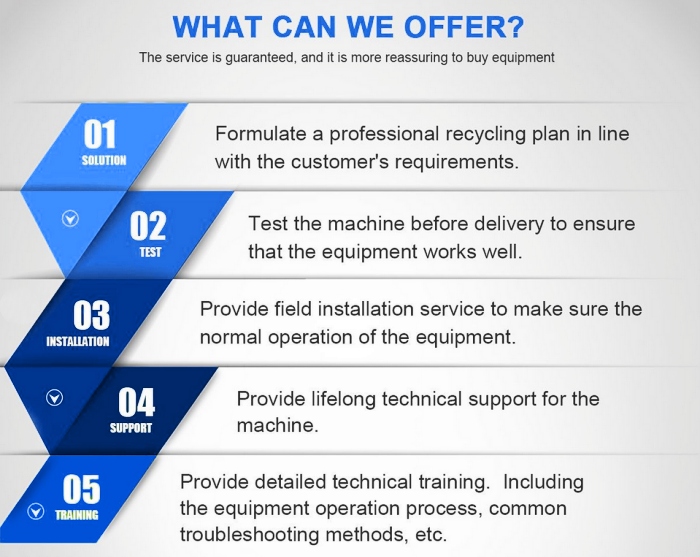

Supplier Reputation and Support: When selecting a pyrolysis plant supplier, it is essential to examine their local or regional success stories, plant scale, machine quality, and technical capabilities. Pyrolysis plant manufacturers like DOING Company, with years of experience and customized solutions, can provide complete plant construction plans, from throughput to equipment configuration, tailored to the specific needs of the Indonesian market. Furthermore, DOING provides installation, commissioning, operation training, and comprehensive after-sales service (including remote support and on-site technical assistance), and has several completed pyrolysis projects in Indonesia.

DOING pyrolysis plant manufacturer

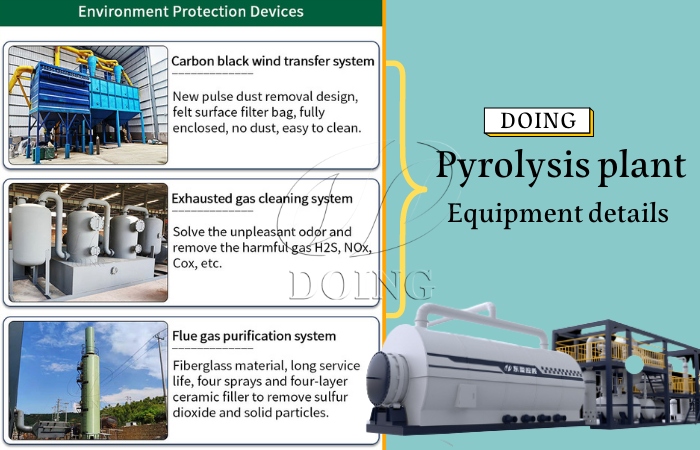

Environmental Compliance and Energy Consumption: Considering Indonesia's increasingly stringent environmental regulations, selecting a pyrolysis plant equipped with advanced environmental protection devices (such as exhaust gas purification systems and desulfurization towers) can minimize emissions and avoid potential legal risks and operational disruptions. Energy efficiency is also a crucial consideration; low-energy designs significantly reduce operating costs. DOING pyrolysis plants can recover non-condensable combustible gases generated during pyrolysis for reactor heating, significantly reducing fuel costs.

DOING pyrolysis plant environment protection devices

Indonesia's waste management landscape, characterized by growing waste volumes and a strong governmental push towards sustainable solutions, presents a fertile ground for pyrolysis plant startups.

For inquiries regarding the startup of comprehensive pyrolysis operations in Indonesia, please feel free to contact DOING Company.

Releate article:

Copyright © 2015-2025.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.