Phone: +86-371-5677-1821

TEL : +86-135-2669-2320

Email: sales@wastetireoil.com

Whatsapp:+86-135-2669-2320

During the crude oil extraction process, crude oil sludge are produced due to drilling, operation, workover, oil production, gathering, storage and other reasons and accidental leakage of equipment and pipelines; when processing oily sewage, a large number of oily waste residues are also produced in the sloping oil separator In addition, oil storage tanks also settle a large amount of oil sludge at the bottom of the tank. Oil fields produce a large amount of oil and soil every day, which accumulates over time. At present, these oil sludge are only collected, stored in the open air, and have not yet been effectively processed.

Crude oil sludge

Crude oil sludge

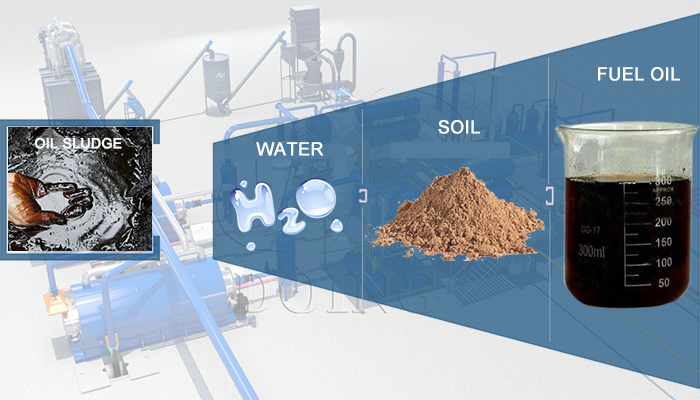

The most reasonable oil sludge treatment plant is pyrolysis plant. Oil sludge pyrolysis plant can convert these oil sludge to clean fuel oil, soil and water, both solving the pollution problem and creating economic benefits.

Oil sludge pyrolysis plant for oil sludge recycling

Oil sludge pyrolysis plant for oil sludge recycling

The oil sludge pyrolysis plant process:

To get better oil output, the oil sludge should be pretreated first. Large aggregates of oil sludge are dispersed by the rotation of the oil sludge sorting wheel, and the oil sludge particles larger than 20mm are pushed into the bulk material collection box on the side of the pretreatment device by the sorting wheel while the oil sludge smaller than 20mm will enter the sludge pretreatment tank through the sieve holes of the sludge sorting screen. Through the combined action of the sludge sorting wheel and the sieve plate, debris removal, fiber crushing, uniform dispersion, sludge storage and transportation are realized.

Then the pre-treated sludge is loaded into oil sludge pyrolysis plant by an automatic feeding system. After the above work is done, heat the reactor. When the temperature reaches to a certain degree, the oil sludge pyrolysis happens and oil gas comes out. The oil and gas pass through the Buffer chamber to release the pressure and enter the condensers. In the condensers, most of the oil gas would be cooled into fuel oil. The uncondensable gas is recycled to reactor for heating, saving fuel.

At last, the pollution control system works. The smoke generated during the entire combustion process is removed by desulfurization and dust removal system until it meets the emission standards.

DOING oil sludge pyrolysis plant project site

DOING oil sludge pyrolysis plant project site

The oil sludge pyrolysis plant can realize the separation of oil, residue and water, and achieve the purpose of recycling resources. And it will not cause secondary pollution. Today, with stricter environmental protection policies, our oil sludge pyrolysis plant is recognized by many customers. If you have any intention to deal with oil sludge, please contact us.

Releate article:

Copyright © 2015-2026.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.