Phone: +86-371-5677-1821

TEL : +86-135-2669-2320

Email: sales@wastetireoil.com

Whatsapp:+86-135-2669-2320

During the waste plastic to fuel oil, carbon black and syn-gas conversation process, pyrolysis reactor design plays a pivotal role in the efficiency, safety, and overall performance of a plastic pyrolysis plant. Here DOING has a specail design mainly for the smooth operation of waste plastic pyrolysis plant, our pyrolysis reactor designs focus on optimizing heat transfer, ensuring safety, and maintaining high product quality.

Pyrolysis plant reactor

Pyrolysis plant reactor

Efficient heating system: Use high calorific value pyrolysis oil as fuel, with low consumption and low cost. The heating system is stable and the inner tank rotates evenly to heat.

Advanced cooling system: The new cold air system has a short cooling time and high efficiency. The rapid cooling device improves production efficiency.

Insulation system design: The all-inclusive insulation shell of DOING waste plastic pyrolysis plant reactor has good insulation effect and reduces energy consumption. The insulation material has both insulation and noise reduction functions to improve safety.

The heating system of pyrolysis plant reactor

The heating system of pyrolysis plant reactor

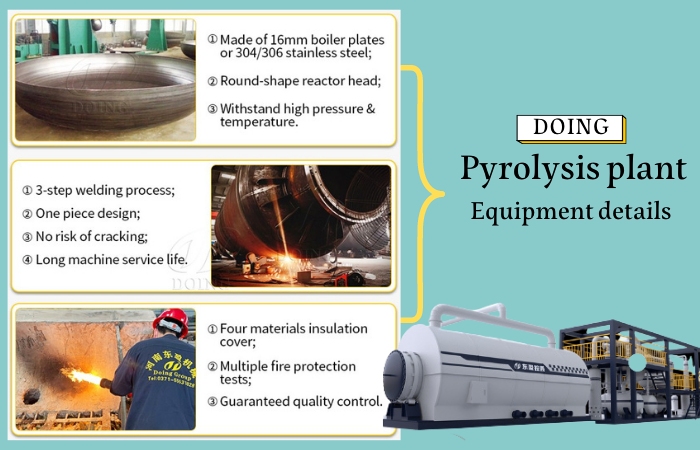

Structural and material safety: The arc head has strong pressure resistance and good welding sealing. High-quality materials extend the life of the whole plastic pyrolysis plant. The reinforcement rib design enhances stability.

Operation and protection safety: The fine steel rail has good heat dissipation and reduces damage to the tugboat. The new tugboat is firmly fixed to avoid displacement and collision. The rear end slot design prevents the outlet from breaking.

Sealing and environmental safety: High-quality graphite packing eliminates air leakage of waste plastic pyrolysis process. Flange connection is easy to repair. The deodorization device and desulfurization tower ensure that the exhaust gas meets the emission standards.

DOING unique welding sealing of pyrolysis plant reactor

DOING unique welding sealing of pyrolysis plant reactor

Optimize process design: Ellipsoidal head and full penetration process improve welding quality. High-quality steel plates adapt to acidic environments. Fine steel rails ensure smooth operation of equipment.

Efficient slag removal and cooling: Two-way slag removal ports of the plastic pyrolysis reactor designed by DOING Company shorten slag removal time. Rapid cooling system reduces cooling waiting time and ensures product quality.

Quality and environmental advantages: Fully enclosed insulation shell reduces energy consumption and stabilizes product quality. Environmental protection devices ensure production continuity and improve overall quality stability.

DOING pyrolysis reactor details

DOING pyrolysis reactor details

Among many plastic refining raw materials, PE plastic is prone to wax deposition during pyrolysis. Therefore, special attention should be paid to wax deposition during process design of plastic pyrolysis plant. Henan DOING waste plastic pyrolysis plant can customize decoking scrapers and decoking energy balls to alleviate the coking and wall adhesion during plastic pyrolysis.

In conclusion, the design of the reactor in a plastic pyrolysis plant is not just a technical detail but a critical factor that directly impacts the plant's ability to produce high-quality products efficiently and sustainably. At Henan DOING, we are committed to continuous innovation and optimization of our plastic pyrolysis plant reactor designs. By focusing on enhancing heat transfer efficiency, ensuring the highest levels of safety, maintaining consistent product quality, minimizing environmental impact, and offering unparalleled operational flexibility.

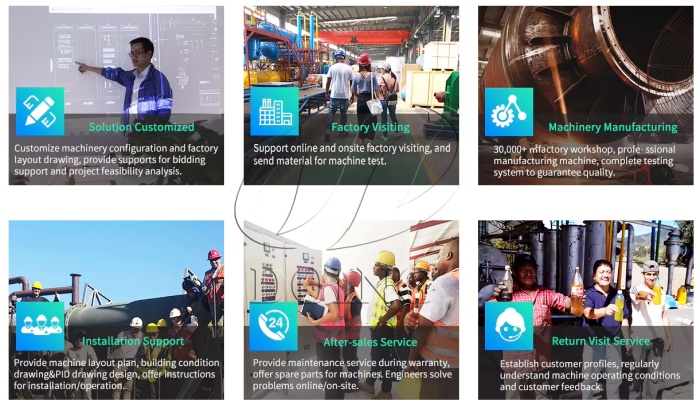

Manufacturer professional services of pyrolysis plant

Manufacturer professional services of pyrolysis plant

If you have corresponding needs of specially designed pyrolysis plant, please contact us. Our professional business and engineering team work together to provide you with comprehensive services.

Releate article:

Copyright © 2015-2025.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.