Phone: +86-371-5677-1821

TEL : +86-135-2669-2320

Email: sales@wastetireoil.com

Whatsapp:+86-135-2669-2320

The global challenge of plastic waste is undeniable. Millions of tonnes of plastic end up in landfills or polluting our oceans each year, posing severe environmental threats. However, this problem also presents a significant opportunity. At Henan Doing Company, we are at the forefront of a transformative solution: plastic pyrolysis, turning problematic soft plastic waste into a valuable and sustainable energy resource.

Driven by our commitment to waste to energy treatment solution and environmental stewardship, we offer advanced plastic pyrolysis machines designed to efficiently convert post-consumer and post-industrial plastic waste into high-quality plastics to oil. This process not only addresses the plastic pollution crisis but also contributes to a circular economy and energy security.

Soft plastic recycling pyrolysis machine

Soft plastic recycling pyrolysis machine

Soft Plastic Pyrolysis Feedstock: What Can We Process?

Our plastic pyrolysis machines are specifically engineered to handle a wide range of soft plastic waste that often proves difficult to recycle through traditional mechanical methods. This includes:

①Polyethylene (PE):

Low-Density Polyethylene (LDPE): Plastic films, bags, agricultural films, shrink wrap.

High-Density Polyethylene (HDPE): Bottles, containers, pipes.

②Polypropylene (PP): Woven bags, containers, automotive parts, bottle caps.

③Polystyrene (PS): Foam packaging, disposable cutlery, CD cases.

Soft plastic recycling feedstocks for pyrolysis machine

Soft plastic recycling feedstocks for pyrolysis machine

Crucially, our technology excels in processing mixed plastic streams and contaminated plastics, reducing the need for extensive pre-sorting and cleaning, which often limits conventional recycling. This makes our solution ideal for dealing with mixed municipal solid waste streams and post-consumer packaging waste.

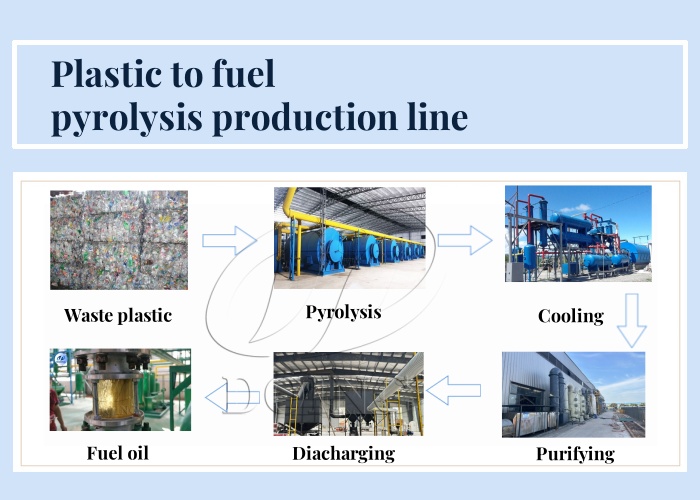

Pyrolysis Process: Step-by-Step Plastic to Oil Transformation

Our plastic pyrolysis machine employs a sophisticated, thermal decomposition process in the absence of oxygen. This ensures a safe, controlled, and highly efficient conversion of plastic polymers into valuable liquid fuels and other by-products.

Soft plastic recycling pyrolysis process

Soft plastic recycling pyrolysis process

Pre-treatment & Feeding:

Shredding(Optional): Waste plastics are typically processed into smaller, manageable pieces to ensure efficient feeding and uniform pyrolysis. This is a critical step for consistent reactor performance.

Automated Feeding System: Our soft plastic to fuel oil pyrolysis machines are equipped with robust, automated feeding mechanisms that ensure a continuous and controlled introduction of plastic feedstock into the pyrolysis reactor. This minimizes manual handling and enhances operational safety.

Thermal Decomposition (Pyrolysis)

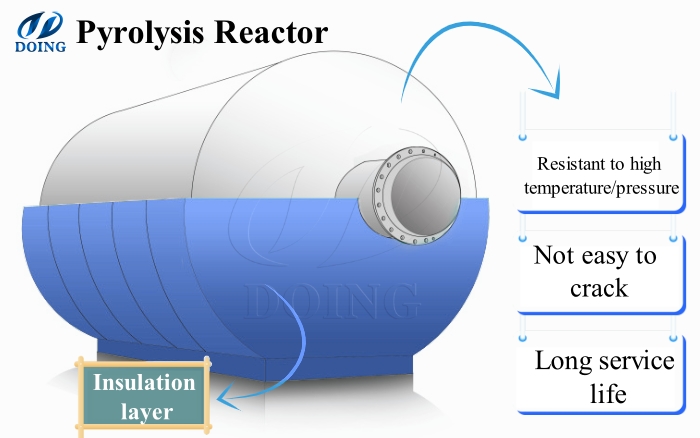

Heating and Cracking: The shredded plastic is heated in a sealed pyrolysis reactor to high temperatures (typically between 300°C to 500°C) under an inert atmosphere. The absence of oxygen prevents combustion, instead breaking down the long polymer chains into smaller hydrocarbon molecules. The heat causes the plastic materials to crack and vaporize, forming a mix of oil gases.

DOING plastic recycling pyrolysis reactor design advantages

DOING plastic recycling pyrolysis reactor design advantages

Condensation & Oil Production

Vapor Cooling: The hot vapors are then passed through a series of heat exchangers (condensers).

Liquefaction: As the oil gas cool, they condense into a liquid fuel, commonly referred to as plastic pyrolysis oil or plastic-to-oil fuel. This oil is a versatile byproduct that can be further refined or used as a substitute for fossil fuels in various industrial applications, such as power generation, cement kilns, or even as bunker fuel after appropriate refining.

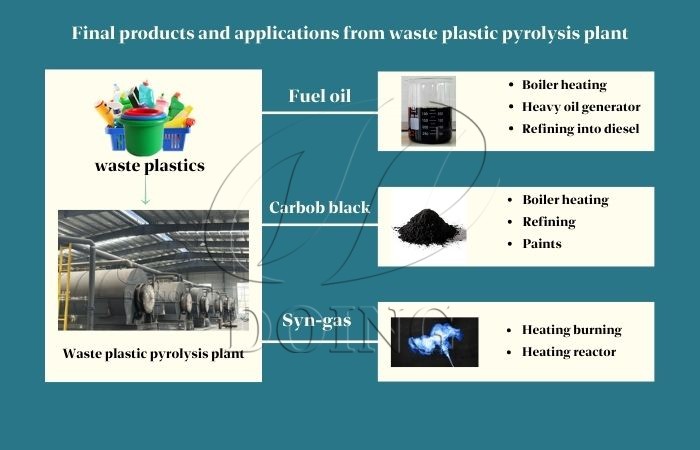

Gas Recovery & Byproduct Management

Non-Condensable Gases (NCG): Any gases that do not condense are captured. These syngases can be used to provide the energy needed to heat the pyrolysis reactor, making the process largely self-sustaining and reducing external energy requirements.

Solid Residue (Carbon Black/Char): A small amount of solid residue, primarily carbon black, remains in the reactor. This carbon black can be a valuable byproduct, used in industries like tire manufacturing, pigment production, or as a soil amendment.

Benefits of Our Plastic Pyrolysis Machine Solution

Adopting our plastic pyrolysis technology offers a multitude of advantagable resource, aligning with circular economy principles.

Valuable Product Generation: Produces plastic pyrolysis oil and carbon black, both of which have significant market value.

Reduced Waste Disposal Costs: Eliminates or significantly reduces the costs associated with traditional landfilling or incineration.

Handles Mixed & Contaminated Plastics: Significantly reduces the stringent pre-sorting requirements of mechanical recycling.

Energy Self-Sufficiency: The captured syngas can power the plant, leading to lower operational energy costs.

Versatile Application of Products: The generated oil can be used in various industries, providing a stable revenue stream.

Soft plastic recycling pyrolysis products and applications

Soft plastic recycling pyrolysis products and applications

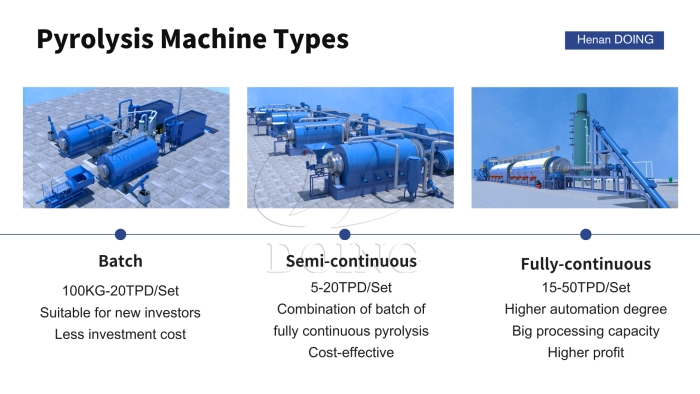

Technological Superiority of DOING Plastic to Oil Pyrolysis Solution

We are dedicated to providing comprehensive solutions that address the global plastic waste crisis. We offer a range of plastic pyrolysis machine sizes and operation modes to meet diverse waste soft plastic recycling and processing needs, from small-scale community projects to large industrial plastic recycling pyrolysis facilities.

Different types of soft plastic recycling pyrolysis machines for sale

Different types of soft plastic recycling pyrolysis machines for sale

Whether you are a waste management company, an industrial facility looking for alternative fuel sources, or an environmental organization championing innovative pyrolysis plastic to oil recycling solutions, Henan Doing Company is your trusted partner.

Contact us today for a consultation and discover how our advanced plastic pyrolysis machine can revolutionize your soft plastic to oil recycling strategy.

Releate article:

Copyright © 2015-2025.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.