Phone: +86-371-5677-1821

TEL : +86-135-2669-2320

Email: sales@wastetireoil.com

Whatsapp:+86-135-2669-2320

Plastic, also known as white pollution, has been plaguing governments and people of various countries. Many countries are studying how to deal with these plastic wastes in an environmentally friendly way. There is a good technology----Plastic pyrolysis, which could convert the plastic into fuel oil which is a very good heating fuel way. But How efficient is plastic pyrolysis in waste plastic management?

Plastic Pyrolysis addresses the limitations of the following plastic management recycling ways:

Landfilling: consume large amounts of land, contribute to soil and groundwater pollution, and release methane, a potent greenhouse gas, as plastics degrade.

Incineration: The combustion process in incineration produces harmful air pollutants such as dioxins and particulate matter. Additionally, incineration requires continuous energy inputs.

Mechanical recycling: It often requires plastics to be sorted by type and in good condition, making it impractical for mixed or contaminated plastic waste.

Waste plastic pyrolysis plant benefits

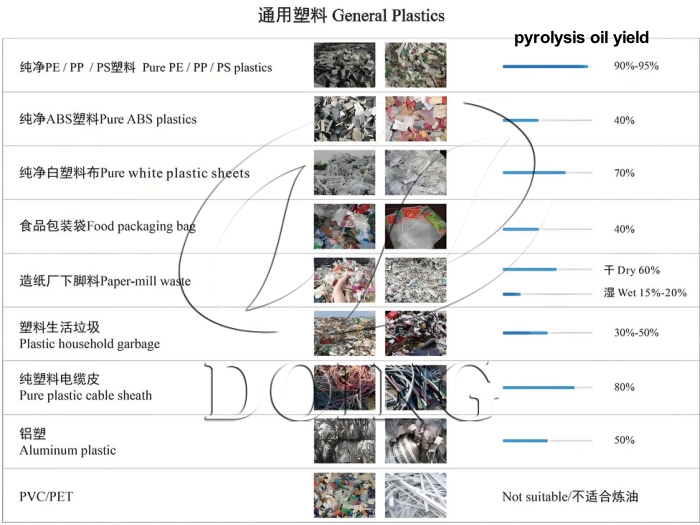

•Raw materials input vs. products output : Plastic pyrolysis operates on the principle of breaking down waste plastics into their constituent chemicals through high temperatures in an oxygen-free environment. The efficiency of this process is typically measured by evaluating the output of its products (e.g., syngas and fuel oil) relative to the raw materials input required to operate the pyrolysis unit. Energy efficiency ranges from 40% to 75%, depending on factors such as the type of plastic being processed, the specific pyrolysis technology used, and operational conditions. DOING's waste plastic pyrolysis plants utilize advanced technology and can process a variety of waste plastics, including PP/PE/PS/ABS, paper mill waste, and plastic woven bags. Please note that PET and PVC are not suitable for pyrolysis.

Raw materials of plastic pyrolysis plant and their pyrolysis oil yield

•Self-Sufficiency: One key feature of advanced pyrolysis plants is their ability to achieve energy self-sufficiency. By recovering syngas or a portion of the produced oil as fuel, thereby reducing external energy requirements and enhancing overall efficiency. DOING's waste plastic pyrolysis plants can achieve this.

DOING plastic pyrolysis plant syngas recovery system

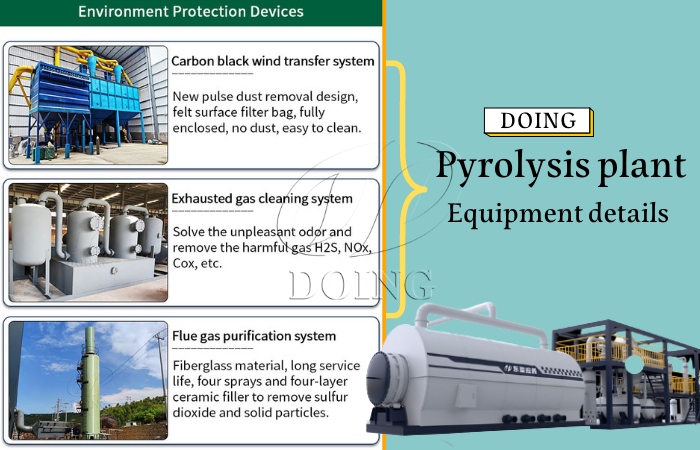

•Emissions: Properly designed pyrolysis systems produce significantly fewer air pollutants than traditional waste management methods like incineration. Because pyrolysis occurs in the absence of oxygen, it avoids the direct combustion of plastics and thus minimizes harmful emissions. However, careful management of emissions from the pyrolysis of waste plastics is also necessary to ensure compliance with environmental regulations. DOING's waste plastic pyrolysis plants are equipped with comprehensive environmental protection facilities to ensure the entire waste plastic pyrolysis process is environmentally friendly and pollution-free.

DOING waste plastic pyrolysis plant environment protection devices

•Waste Reduction: Additionally, pyrolysis helps reduce the volume of plastic waste sent to landfills. By diverting plastic waste from landfills, pyrolysis helps mitigate greenhouse gas emissions associated with waste decomposition and reduces landfill space demands.

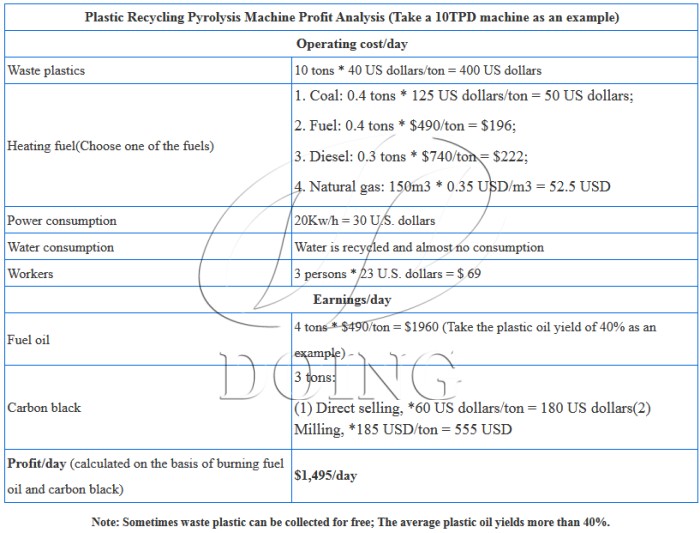

•Capital and Operating Costs: While the capital costs of establishing a waste plastic pyrolysis plant can be high, the process offers promising economic benefits over time. The sale of valuable by-products such as fuel oil and carbon black can offset operational expenses.

Final products and applications from waste plastic pyrolysis plant

Waste plastic pyrolysis plant profit analysis

•Market Demand: Additionally, the profitability of pyrolysis depends on the market demand for its products, which varies with regional energy prices and regulatory frameworks. In regions with high demand for alternative energy sources, waste plastic pyrolysis plants can achieve greater economic returns.

In summary, plastic pyrolysis is a highly efficient and environmentally friendly solution for waste plastic management. By optimizing energy efficiency, reducing environmental impact, and offering economic benefits, pyrolysis holds great potential for converting plastic waste into valuable resources. While challenges remain in scaling and optimizing the pyrolysis technology, continuous innovation—such as companies like DOING—is enhancing its efficiency and accessibility.

DOING waste plastic pyrolysis plant manufacturer services

If you are interested in learning more about pyrolysis technology and how it can be integrated into your waste management strategy, visit our website for detailed information and case studies:

Releate article:

Copyright © 2015-2025.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.