Phone: +86-371-5677-1821

TEL : +86-135-2669-2320

Email: sales@wastetireoil.com

Whatsapp:+86-135-2669-2320

Pyrolysis reactors are the core of waste-to-energy pyrolysis systems, where materials like used rubber tires or scrap plastics are broken down into regenerated pyrolysis oil, gas, and carbon black. A well-designed pyrolysis reactor ensures efficiency, safety, and longevity.

At DOING, our pyrolysis reactors consist of 7 critical components, each engineered for performance and adaptability. Here’s how they work:

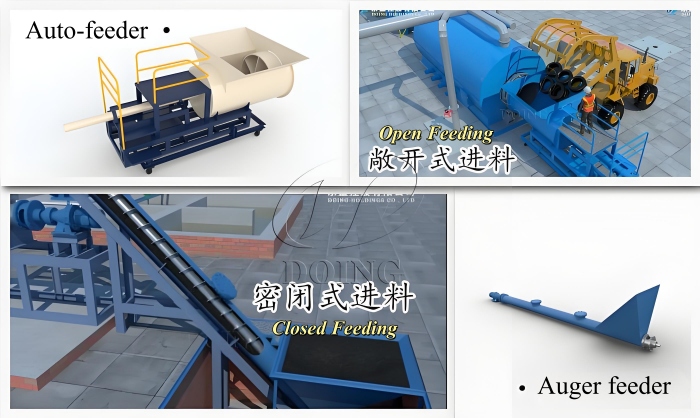

The feeding port is the entry point for raw materials into the reactor. At DOING, we understand that different feedstocks and production scales require tailored solutions. Therefore, we offer customizable feeding port diameters to match specific client requirements. This customization can be integrated with corresponding automatic feeding machines, ensuring a smooth and controlled input of materials into the reactor.

DOING pyrolysis reactor feeding port

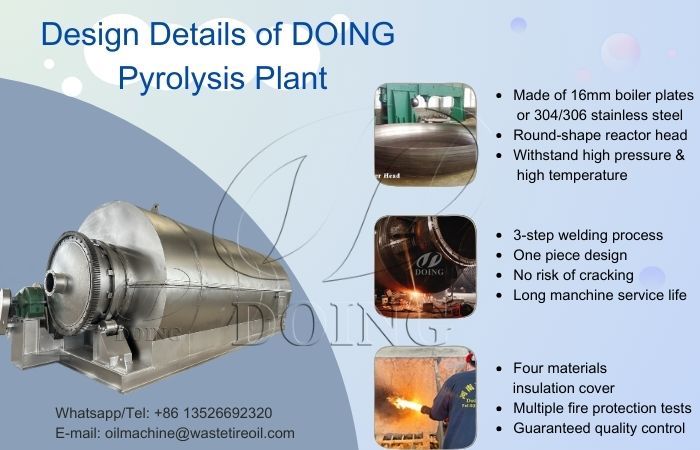

The pyrolysis reactor furnace is the primary chamber where the thermal decomposition of organic waste materials occurs. It consists of two main sections: the head and the furnace body.

Head: DOING reactors feature a curved head design. These heads are precision-pressed by specialized manufacturers, providing superior pressure resistance and structural integrity. This design ensures the tank remains robust and undeformed, even under demanding operating pressures.

Furnace Body: The furnace body is constructed using fully automatic submerged arc welding, a process that guarantees high welding accuracy and exceptional seam strength. The material selection for the furnace body can be customized to meet client specifications, offering options like standard boiler plate or stainless steel. The thickness typically ranges from 14 to 22 millimeters, depending on the operational environment and material requirements.

DOING pyrolysis reactor furnace details

Furthermore, the internal structure of the furnace body can be adapted based on the specific needs of the feedstock material. This may involve the integration of specialized components, such as dewaxing(for pe plastic recycling) or descaling devices(for waste oil sludge treatment), to enhance the efficiency and purity of the pyrolysis process.

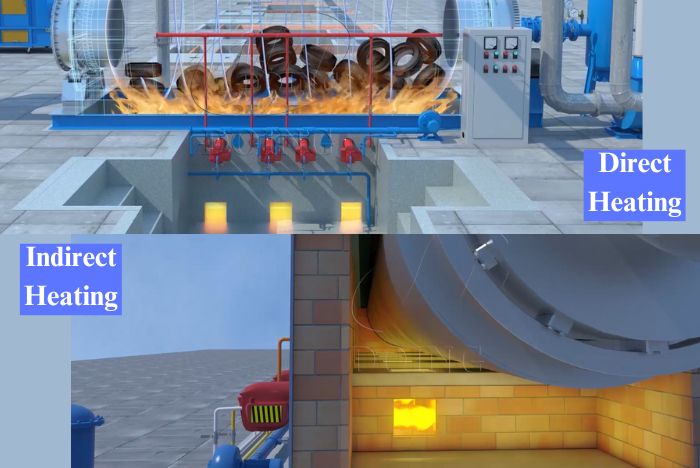

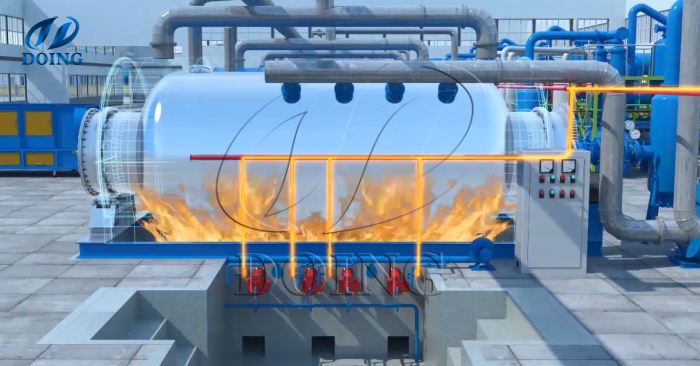

Our batch and semi-continuous pyrolysis reactors utilize a direct heating method. This involves a dedicated combustion chamber located beneath the reactor, equipped with multiple burners and tail gas spray guns. And our fully continuous pyrolysis reactors adopts undirect heating way, which can be heated by hot air furnace to ensure the long service life.

DOING pyrolysis reactor heating methods

Upon system startup, the burners ignite and heat the combustion chamber. Once the target temperature is reached, the pyrolysis reaction commences, generating both valuable oil gas and tail gas. The tail gas undergoes a process of desulfurization and deodorization before being reintroduced into the heating system via the spray guns. This allows for the recycling of process gases, contributing to energy efficiency and reduced emissions.

DOING pyrolysis reactor syngas recycling system

To maintain optimal operating temperatures and enhance safety, our reactors are enclosed in a fully integrated outer insulation shell. This shell is constructed with a multi-layer design and incorporates a specialized sealed groove structure.

This advanced insulation system offers several benefits:

①Superior Thermal Efficiency: It significantly reduces heat loss, leading to lower fuel consumption.

②Enhanced Safety: The robust design and effective sealing prevent uncontrolled heat escape and potential fire hazards or smoke leakage, ensuring a safer operating environment.

DOING pyrolysis reactor outer insulation shell

The transmission system is crucial for the stable and uniform operation of the reactor. It is comprised of sturdy support rollers, high-precision steel guide rails, and a reliable reduction gear mechanism.

Through optimized engineering, this system ensures that the reactor’s contents are subjected to consistent heat distribution throughout the pyrolysis cycle. It also provides enhanced stability, allowing the equipment to operate reliably under continuous high-temperature conditions.

Efficient removal of solid residue (slag) after the pyrolysis process is essential. DOING reactors are designed with flexibility in mind, offering three distinct slag discharge configurations:

Side discharge port, Front discharge port and Rear discharge port.

The specific type and placement of the slag discharge port can be customized based on the operational workflow and material unloading requirements of each client.

DOING pyrolysis reactor salg discharge port

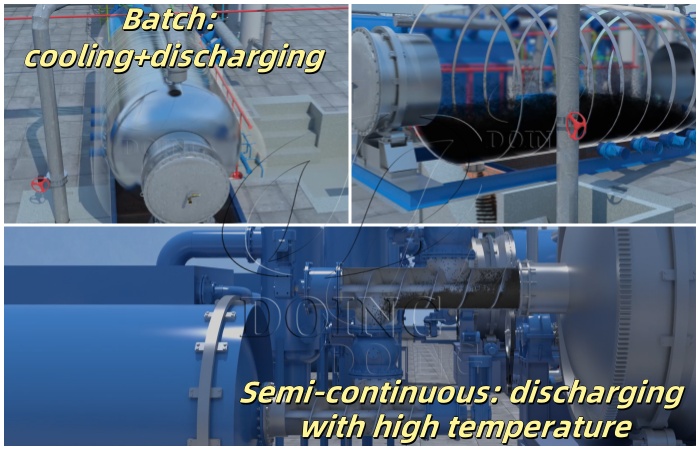

Post-pyrolysis cooling is a critical step before material discharge. Our cooling system, consisting of air intake and air exhaust components, facilitates rapid temperature reduction.

By enabling swift air circulation and heat exchange, this system efficiently lowers the reactor's temperature. The high efficiency of the cooling system integrated into DOING’s batch pyrolysis reactors can significantly reduce the downtime required for cooling, by up to 50%.

DOING pyrolysis reactor cooling system

The design of DOING pyrolysis reactors is a testament to our commitment to practicality, safety, and cost-effectiveness. Each component is engineered to work synergistically, delivering reliable performance in waste-to-energy applications.

For more detailed information on our pyrolysis reactor specifications or to discuss your specific project needs, please do not hesitate to contact DOING. We offer multiple pyrolysis reactir customization options to meet specific operational needs, from material choices to design specifications. Our commitment to quality is evident in every detail.

Releate article:

Copyright © 2015-2025.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.