Phone: +86-371-5677-1821

TEL : +86-135-2669-2320

Email: sales@wastetireoil.com

Whatsapp:+86-135-2669-2320

Polyethylene (PE), the most widely used plastic globally, exists in various forms—all of which are highly suitable for pyrolysis recycling. Pyrolysis technology can effectively decomposes PE's long hydrocarbon chains in a high-temperature, oxygen-free environment, recycling various types of polyethylene (PE) plastic into valuable products like fuel oil, gas, and wax. The main types of PE waste suitable for pyrolysis include:

DOING plastic pyrolysis machine site

DOING plastic pyrolysis machine site

1.High-Density Polyethylene (HDPE)

HDPE is rigid and found in:

Rigid containers: Milk jugs, detergent bottles, shampoo containers, plastic crates.

Pipes and fittings: Industrial and plumbing pipes, often with residual chemicals.

Plastic Lumber and Outdoor Furniture: Used in construction and landscaping.

2.Low-Density Polyethylene (LDPE)

LDPE is flexible and commonly used in:

Packaging materials: Plastic bags, retail carry-out bags, cling films, shrink wraps, bubble wraps, and some food packaging (e.g., for detergents or food).

Agricultural films: Greenhouse covers and mulch films, often contaminated with dirt or pesticides.

3.Linear Low-Density Polyethylene (LLDPE)

LLDPE combines flexibility and strength, used in:

Stretch films: Pallet wraps, bubble wrap and industrial packaging.

Liners and covers: Pond liners, landfill covers, and geomembranes.

4.Cross-Linked Polyethylene (XLPE) Waste

XLPE, used in high-performance applications like:

Electrical cables: Insulation for power lines.

Pipe insulation: For hot water systems, under-floor heating pipes, automotive wire harnesses and industrial ducts.

5.Mixed PE films

Contaminated PE packaging, and multilayer PE-based materials (if properly sorted).

Food pouches (PE/Al/PA), toothpaste tubes, aseptic cartons

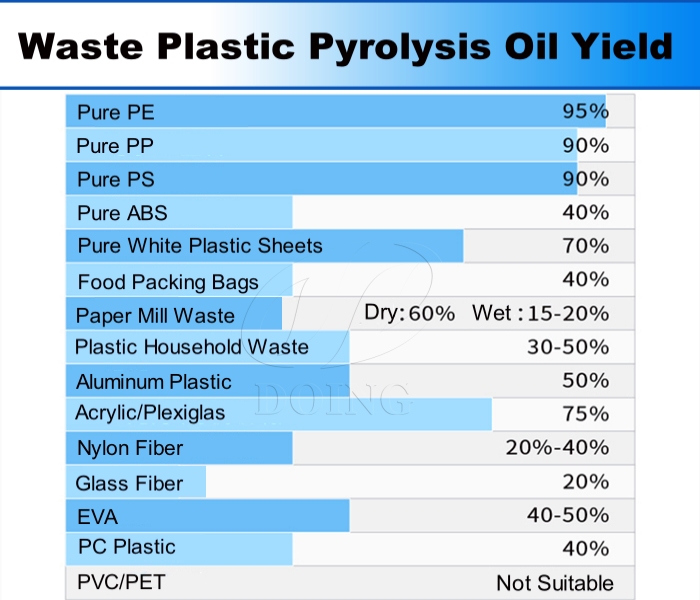

Plastic pyrolysis oil yield

Plastic pyrolysis oil yield

Why pyrolysis is ideal for polyethylene waste, that because mechanical recycling faces challenges:

Degradation: Each time plastic is mechanically recycled, its polymer chains break down, reducing the quality of the final product.

Contamination: Food residue, labels, and other contaminants can render plastic unsuitable for mechanical recycling.

Mixed Plastics: Separating different types of plastic is costly and often impractical.

DOING pyrolysis technology overcomes these hurdles. Instead of physically remelting the plastic, pyrolysis uses heat in an oxygen-free environment to break down the long polymer chains of polyethylene into their original building blocks: hydrocarbons, which is incredibly valuable:

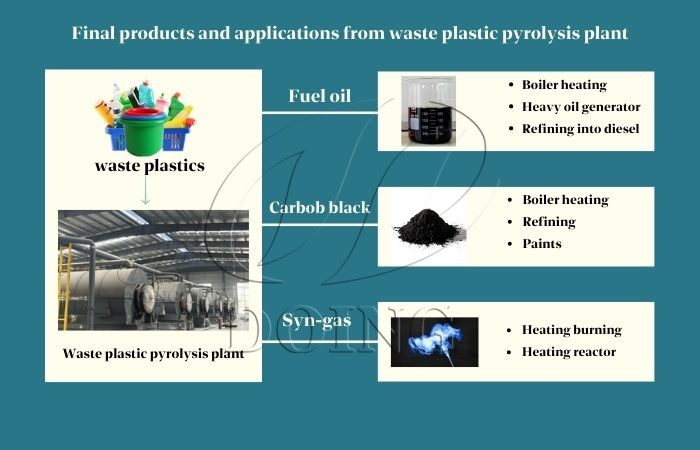

Pyrolysis Oil: A synthetic oil that can be used as a fuel oil substitute in boiler heating, gypsum plants, glass plants, brick plants, steel plants, cement plants,or further refined into diesel in heavy machine and diesel generator.

Syn-Gas (Syngas): A mixture of gases that can be recycled to fuel the pyrolysis reactor itself, making the process self-sustaining.

Carbon Black: A solid residue that can be used as a reinforcing agent in new rubber products, as a pigment, or as a construction material additive.

Plastic pyrolysis product application

Plastic pyrolysis product application

PE plastics produce wax oil during the pyrolysis process. DOING has achieved a significant breakthrough in solving this problem ( Recommended Reading: Understanding Wax Oil in Plastic Pyrolysis Process) If you are looking for a reliable, efficient, and profitable solution to recycle HDPE, LDPE, LLDPE and other plastic wastes(PP, PS, ABS), contact DOING right now.

Releate article:

Copyright © 2015-2025.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.