Phone: +86-371-5677-1821

TEL : +86-135-2669-2320

Email: sales@wastetireoil.com

Whatsapp:+86-135-2669-2320

Agricultural plastic films (mainly PP, LDPE/HDPE mulch) widely used for greenhouse covering, mulching, and silage, boosting crop yields. However it also leaves behind one of the most stubborn waste streams on the planet—thin, contaminated, soil-laden film. Traditional agricultural plastic films recycling methods require high feedstock quality and struggle with their dirt, pesticide residues, and mixed materials.

DOING agricultiral plastic film pyrolysis equipment

DOING agricultiral plastic film pyrolysis equipment

But pyrolysis equipment offers an innovative and sustainable solution to address agricultural plastic films pollution while recovering valuable resources. Pyrolysis is a thermal decomposition process in an oxygen-free environment to recycle agricultural plastic films into valuable resources: fuel oil, carbon black and gas, while also addressing the plastic pollution problem. DOING has developed and designed pyrolysis equipment specifically for recycling agricultural plastic film, and it has been purchased and is currently in operation in many regions, making it an ideal choice for customers seeking agricultural plastic film recycling solutions.

The following is a detailed introduction to the DOING agricultural plastic film pyrolysis equipment, including its process and advantages

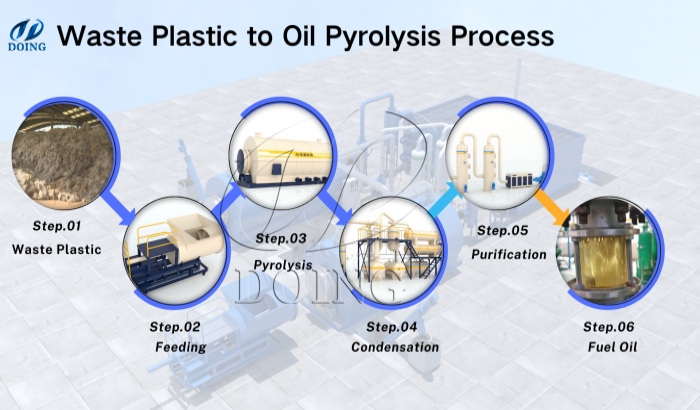

DOING Pyrolysis Equipment Process for Agricultural Plastic Film Recycling

1.Collecting Agricultural Plastic Film

Farmers gather used plastic mulch film, silage covers, or greenhouse films.

2.Pre-treating Agricultural Plastic Film

Agricultural plastic film with high levels of contaminants (soil, debris, moisture) can be removed by washing, drying, and pulverizing to increase oil yield.

3.Feeding Agricultural Plastic Film into Pyrolysis Reactor

Pre-treated agricultural plastic film is fed into the sealed pyrolysis reactor using manual or automatic feeders, conveyors, screw conveyors, or other methods.

DOING agricultiral plastic film pyrolysis equipment process

DOING agricultiral plastic film pyrolysis equipment process

4.Pyrolysis Agricultural Plastic Film

Agricultural plastic film undergoes thermal decomposition in an oxygen-free environment at 350-600°C. This breaks down long-chain polymers into:

Pyrolysis Oil (60–95% yield): A fuel used in generators, or boilers, which, after refinement, can be converted into diesel to power agricultural machinery, reducing reliance on fossil fuels.

Carbon Black (5–20% yield): A solid byproduct used as a soil amendment (enhancing water retention) or sold to rubber/construction industries.

Syngas (10–30% yield): This non-condensable, combustible gas can be reused to heat the reactor, making the process energy-self-sufficient.

DOING agricultiral plastic film pyrolysis equipment applications

DOING agricultiral plastic film pyrolysis equipment applications

DOING Pyrolysis Equipment Advantages for Agricultural Plastic Film Recycling

1.Significant Economic Benefits

A DOING agricultural film pyrolysis equipment capable of processing 10 tons of agricultural film per day can produce approximately 8 tons of pyrolysis oil per day, which sells for $600-900 per ton. In some regions, agricultural film recycling and processing offers subsidies, providing stable income for farms or recycling organizations.

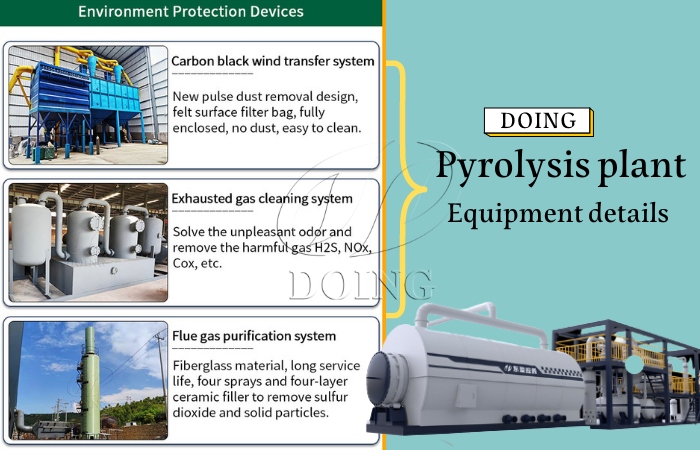

2.Environmental

Unlike landfills or incineration, pyrolysis leaves no toxic runoff or heavy emissions, aligning with eco-friendly farming goals. The non-condensable, non-combustible gas is purified to acceptable discharge standards by the DOING Environmental Protection waste gas treatment unit. Furthermore, a water recycling system is employed, eliminating wastewater generation.

DOING agricultiral plastic film pyrolysis equipment environmentally

DOING agricultiral plastic film pyrolysis equipment environmentally

3.Flexibility

From small farm-based units to large regional recycling hubs, DOING offers 0.1–50 TPD models agricultural plastic pyrolysis equipment. Mobile or small-scale DOING units (0.1–5 TPD) can be installed near farmland, reducing transportation costs and turning local waste into on-site fuel.

4.Rugged design

The pyrolysis reactor is constructed of corrosion-resistant steel, capable of processing films containing pesticides, and features a patented wax removal device for improved operational efficiency.

5.Farm-friendly support

DOING provides pyrolysis equipment installation services, localized training, and 24/7 technical support, ensuring smooth operation even in remote locations.

DOING provide perfect service

DOING provide perfect service

For those who want a perfect solution for recycling agricultural plastic films , pyrolysis is not only a recycling method, but also a way to turn a burden into a resource. Furthermore, DOING plastic pyrolysis equipment can not only recycle PP, PE agricultural plastic films, but also ABS and PS plastics, paper mill scraps, and aluminum-plastic products (pharmaceutical vacuum packaging, snack packaging, beverage bottle packaging bags, welding wire packaging bags, aluminum-plastic film scraps, building material decorative aluminum-plastic panels, aluminum edge paper, etc.). If you are interested in a specific pyrolysis equipment model or more detailed process steps, please feel free to leave a message.

Releate article:

Copyright © 2015-2025.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.