Phone: +86-371-5677-1821

TEL : +86-135-2669-2320

Email: sales@wastetireoil.com

Whatsapp:+86-135-2669-2320

Indonesia is one of the world’s largest contributors to marine plastic pollution, with an estimated 0.48 to 0.8 million metric tons of mismanaged plastic waste entering the ocean annually. The country faces significant challenges in managing its growing volume of plastic waste, due to factors such as rapid urbanization, limited waste collection infrastructure, and low recycling rates. To address this pressing issue, we recommend the adoption of pyrolysis technology to recycle plastic waste in Indonesia.

Pyrolysis technology is a thermal decomposition process that breaks down plastic waste in the absence of oxygen, converting it into valuable products such as pyrolysis oil, gas, and carbon black. This process significantly reduces the volume of plastic waste that would otherwise end up in landfills or oceans.

Compared to open burning or landfilling, pyrolysis technology produces fewer harmful emissions when properly managed, contributing to cleaner air and water. Open burning releases a large amount of harmful gases such as dioxins and furans, which can cause respiratory diseases and other health issues. Landfilling also poses risks of groundwater contamination. Pyrolysis technology, on the other hand, operates in a closed system, effectively controlling the emission of harmful gases and reducing environmental pollution.

Waste plastic recycling pyrolysis technology

One of the major advantages of pyrolysis technology is its ability to convert plastic waste into usable products:

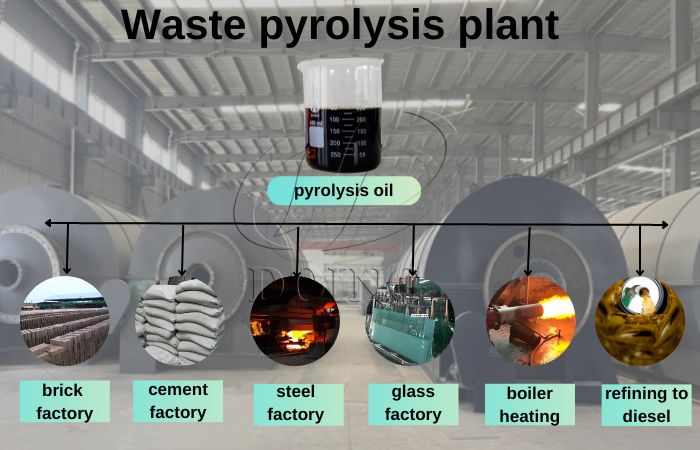

Pyrolysis Oil: The pyrolysis oil obtained from pyrolysis machines has extensive industrial applications. It can serve as a renewable fuel in industrial furnaces, boilers, and kilns across sectors such as steel, glass, and ceramics, effectively reducing dependence on traditional fossil fuels. Through advanced refining, pyrolysis oil can be converted into high-quality non-standard diesel fuel for use in generators, heavy machinery, and other applications. Additionally, it can function as a versatile chemical feedstock, supplying essential raw materials for the production of plastics, rubber, and various chemical products.

Applications of plastic pyrolysis oil

Synthetic Gas (Syngas): The syngas produced by the pyrolysis machine is a combustible gas mixture composed primarily of hydrogen, carbon monoxide, and methane. This gas can be directly recycled to fuel the pyrolysis machine. This syngas not only reduces energy costs but also helps reduce carbon emissions.

Pyrolysis syngas recovery and incineration

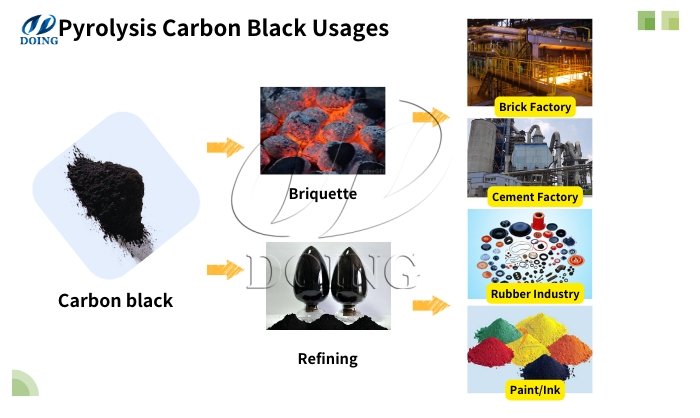

Carbon Black: Carbon black from pyrolysis machines has a high purity level and fine particle size, making it a valuable resource with diverse applications. In the construction industry, it can be used as a reinforcing and functional additive in concrete production. Its addition can enhance concrete's strength, improve its impermeability and corrosion resistance, and extend the lifespan of structures. In the rubber industry, carbon black serves as a reinforcing agent to improve the strength, abrasion resistance, and aging resistance of rubber products, such as tires, rubber hoses, and rubber belts. Furthermore, carbon black can be processed into high-value products like ink, coatings, and plastic additives, expanding its application scope and economic value.

Plastic pyrolysis carbon black usages

These by-products offer economic opportunities and support a circular economy model, which aligns with Indonesia’s goals for sustainable development.

The by-products of pyrolysis technology have significant economic value. Pyrolysis oil can be sold to power plants or chemical companies, syngas can be supplied to industrial enterprises, and carbon black can be marketed to construction and cement firms. This not only generates economic benefits for pyrolysis plants but also stimulates the development of related industries, creating more job opportunities.

In addition, the application of pyrolysis technology can reduce Indonesia’s reliance on imported fossil fuels. By converting plastic waste into energy and chemical feedstocks, the country can enhance its energy self-sufficiency and reduce energy costs.

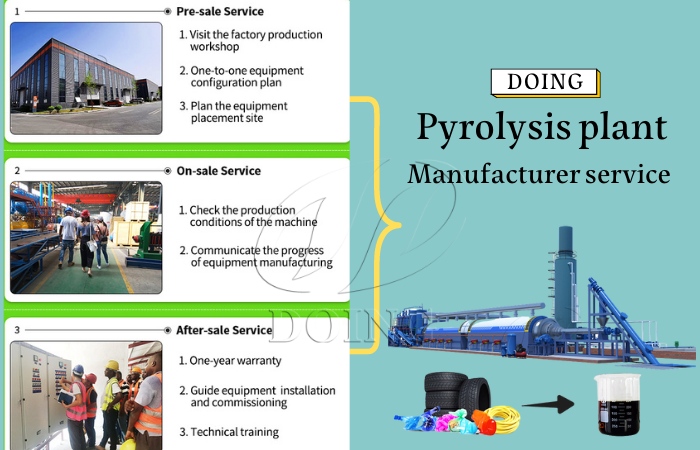

DOING plastic pyrolysis machine manufacturer

Pyrolysis technology offers an effective solution to the plastic waste problem in Indonesia, with advantages such as reducing environmental pollution and producing valuable by-products. Whether your goal is plastic waste disposal or recycling, pyrolysis technology offers a viable solution. If you're considering establishing a plastic pyrolysis project in Indonesia, Henan Dongying can provide you with a customized solution, pyrolysis machine, and comprehensive technical guidance.

Releate article:

Copyright © 2015-2025.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.