Phone: +86-371-5677-1821

TEL : +86-135-2669-2320

Email: sales@wastetireoil.com

Whatsapp:+86-135-2669-2320

In recent years, pyrolysis oil has gradually emerged as a promising alternative to fossil fuels and a key component of circular economy strategies. Pyrolysis oil is produced by pyrolyzing solid waste materials such as waste plastics, tires in the absence of oxygen. As governments worldwide tighten regulations on plastic waste and end-of-life tire disposal, pyrolysis waste into fuel oil offers an environmentally superior, economical and sustainable solution compared to landfilling or incineration.

Europe: The EU's stringent plastic waste regulations have spurred Germany, France, the UK, Italy, and others to adopt pyrolysis oil. With a high calorific value of 45MJ/kg, stable combustion, and low sulfur, it serves as a fossil fuel alternative, driving demand in cement and power sectors.

Asia-Pacific: Rapid development and population growth in the region have increased waste output. China, India, South Korea, Thailand, Indonesia, and Vietnam are actively exploring waste-to-energy technologies. Pyrolysis oil's high calorific value and versatility make it suitable for industrial heating and power generation, with demand expected to surge.

North America: Demand in the U.S. and Canada is mainly driven by the chemical and refining industries. Pyrolysis oil's chemical stability and rich composition provide valuable raw materials, with the U.S. leading in demand and Canada actively developing the market.

Africa: Nigeria, South Africa, Kenya, Egypt, and Côte d'Ivoire face waste management challenges amid industrial growth and rising fuel demand. Pyrolysis oil offers a high-calorific, low-emission alternative. Africa's abundant land, waste resources, and low labor costs attract pyrolysis plant investments, with Nigeria and South Africa already exploring the market. Its potential in industrial heating and power generation is significant.

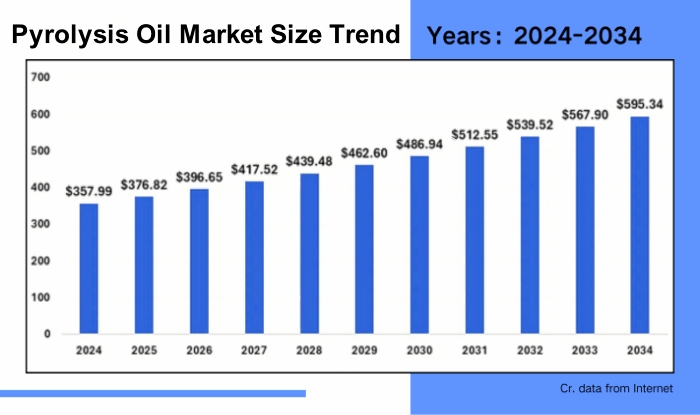

Pyrolysis oil market size trend

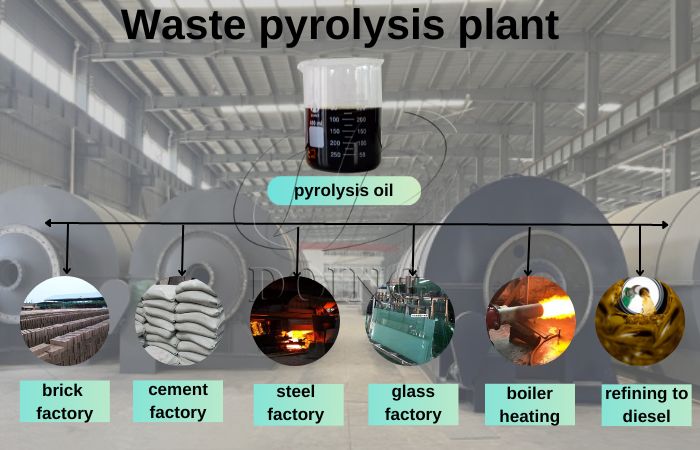

Fuel Oil Replacement: Pyrolysis oil can be directly used as fuel for industrial kilns and boilers for heating or power generation. However, it requires treatment to reduce sulfur content and impurities. Industries such as cement manufacturing and steel production are showing increasing interest in pyrolysis oil as a substitute for traditional fossil fuels.

Applications of pyrolysis oil

Fuel Cost Reduction Through Mixing: Pyrolysis oil can be blended with diesel or heavy oil to cut fuel costs. This application requires filtration and desulfurization optimization.

Further Refining for Diesel: Pyrolysis oil can be upgraded to diesel through waste oil distillation plant. The diesel obtained is often used in heavy machinery, generators, boilers, etc. However, it should be noted that the product of pyrolysis oil distillation is not standard diesel and cannot be used as a new engine oil or lubricant oil for car vehicles. To extract higher quality oil products, the requirements for distillation technology and capital investment are relatively large. Despite the challenges, the demand for refined pyrolysis oil is gradually increasing due to its high-quality energy output.

Applications of non-standard diesel from pyrolysis oil distillation

Extraction of High-Value Chemicals: Pyrolysis oil contains aromatics such as benzene, toluene, and xylene (BTX), which can be used in the production of synthetic resins, dyes, and solvents. It also contains olefins like ethylene and propylene, which serve as raw materials for plastics (e.g., PE, PP).

Production of Asphalt or Carbon Black: The heavy fraction of pyrolysis oil can be used in road paving asphalt or as a reinforcing agent for rubber (carbon black). In the construction industry, pyrolysis oil-derived asphalt offers comparable performance to traditional asphalt while being more environmentally friendly.

The global pyrolysis oil market was USD 1.83 billion in 2024 and is predicted to reach USD 4.51 billion by 2034, growing at a CAGR of 9.45% from 2025 to 2034. Growth is driven by demand for renewable fuels, waste management, and the circular economy. Asia-Pacific dominated in 2024, with North America also expected to grow. Plastics and diesel were the largest segments by feedstock and fuel respectively. With advancements in pyrolysis technology and increasing environmental awareness, the demand for pyrolysis oil is expected to continue growing. The following trends are anticipated:

Technological Innovation: Continuous improvements in pyrolysis technology will enhance the quality and yield of pyrolysis oil, reducing production costs and expanding its application scope.

Policy Support: Governments worldwide are likely to introduce more policies to encourage the development of the waste management pyrolysis oil production industry, such as subsidies and tax incentives, further driving market demand.

Market Expansion: With the rising prices of international fuel resources, people's demand for alternative energy continues to rise. Pyrolysis oil is expected to play a larger role in global energy and chemical markets.

Pyrolysis oil future development trends

In summary, pyrolysis oil holds significant market potential and broad application prospects. As a pyrolysis plant manufacturer, DOING Company is committed to providing high-quality pyrolysis equipment to meet market demands and contribute to the development of the pyrolysis oil industry. Make your pyrolysis oil production process more efficient, with a larger output ratio and greater utilization space!

Releate article:

Copyright © 2015-2025.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.