Phone: +86-371-5677-1821

TEL : +86-135-2669-2320

Email: sales@wastetireoil.com

Whatsapp:+86-135-2669-2320

With the application of plastic recycling technology, converting plastic waste into pyrolysis oil or plastic pellets (granules) has become one of the main waste plastic processing methods. These recycled products—pyrolysis oil and plastic pellets—hold different market values.

Plastic pyrolysis oil V.S. Plastic Pellets

Plastic pyrolysis oil V.S. Plastic Pellets

This article will compare the resale values of these two kinds of waste plastic recycling products, helping businesses and investors make more informed decisions.

1. Overview of Plastic Pyrolysis Oil

Plastic pyrolysis oil is produced through the pyrolysis process, which converts waste plastics into oil. This process typically takes place in an oxygen-deficient environment at high temperatures, where plastic materials undergo pyrolytic decomposition, yielding oil, gas, and carbon as by-products.

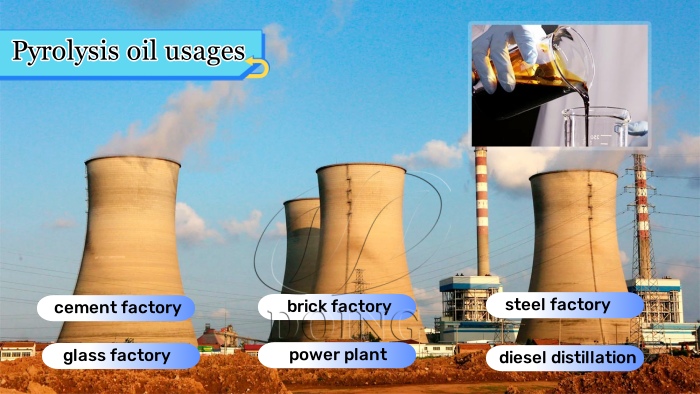

Market Applications of Pyrolysis Oil

·Fuel Use: Plastic pyrolysis oil has a high calorific value of 38 to 45 MJ/kg, making it a viable alternative to traditional fossil fuels. It can be used as fuel oil for industrial furnaces, boilers, and generators in energy-intensive industries such as glass factories, steel mills, power plants, and ceramic factories. For instance, glass factories can use it to provide the high temperatures required for glass melting, while heavy oil power plants can utilize it to generate electricity.

Waste plastic pyrolysis oil market uses

Waste plastic pyrolysis oil market uses

·Refined into Higher-Grade Fuels: After further processing at waste oil refinery plant, plastic pyrolysis oil can be converted into non-standard diesel. This expands its application scope to the transportation sector, meeting the fuel demands of heavy machineries, such as ships, trucks, tractors, etc.

·Environmental Benefits: The use of waste plastics to produce pyrolysis oil helps reduce plastic waste accumulation, offering significant environmental benefits.

Resale Value of Pyrolysis Oil

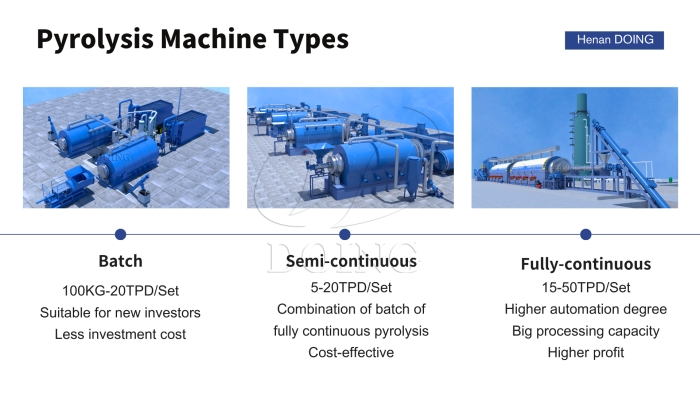

·Technical Investment Requirements: Since the quality of pyrolysis oil obtained from plastic pyrolysis machine is closely linked to the choice of raw materials, the pyrolysis technology, and post-processing, the purity and stability of the product significantly impact its market value.

Different types of plastic pyrolysis technologies

Different types of plastic pyrolysis technologies

·Price Fluctuations: The price of pyrolysis oil is highly influenced by market oil prices, especially during energy crises or oil supply shortages, when the demand for pyrolysis oil as an alternative energy source may increase. According to the data, the selling price of plastic pyrolysis oil will be in the range of $500 to $800 per ton in 2025.

2. Overview of Plastic Pellets (Granulation)

Plastic granulation involves converting waste plastics into plastic pellets through processes like melting, extrusion, and cooling. These pellets can be directly used in the production of new plastic products.

Market Applications of Plastic Pellets

Manufacturing New Plastic Products: Plastic pellets are widely used in the production of products for industries such as automotive, home appliances, construction, and packaging.

Eco-friendly Materials: In some cases, plastic pellets are used to produce eco-friendly building materials or recycled products.

Waste plastic recycling products-plastic pellets

Waste plastic recycling products-plastic pellets

Resale Value of Plastic Pellets

·Stable Demand: The demand for plastic pellets is relatively stable, particularly in industries that require consistent plastic supplies, such as packaging, construction, and automotive. Plastic pellets' prices may range from $880- $1300per ton.

Quality Standards: The price and market value of plastic pellets are directly related to their purity and physical properties (e.g., hardness, toughness). Higher-quality pellets typically fetch higher prices.

·Market Competition: The plastic pellets market is highly competitive, especially when raw material prices fluctuate, which can affect price stability.

Investment requirements for plastic granulation projects:

·Purity: The raw materials must be clean and free of any impurities, such as dirt, sand, stones, metal debris and other foreign matter. Impurities can affect the quality of plastic pellets, reduce their performance, and even damage processing equipment during production. For example, metal impurities can cause equipment wear or failure. Therefore, strict sorting, cleaning and pretreatment of waste plastics are essential to ensure the purity of raw materials.

·Composition: The stable and uniform composition of raw materials is essential. Different types of plastics have different properties, and mixing them will result in inconsistent pellet quality. For example, polyethylene (PE) and polypropylene (PP) can produce high-quality plastic pellets. In contrast, plastics with complex additives or composite materials may bring uncertainty to the pelletizing process. Therefore, it is necessary to classify and select raw materials.

Through comparing pyrolysis oil and plastic pellets, it is evident that both have distinct advantages in terms of resale value, with each exhibiting different market characteristics. Pyrolysis oil's price is heavily influenced by energy markets and can experience significant fluctuations, but it has potential for high returns during energy shortages. On the other hand, plastic pellets offer greater market stability, but the market competition has increased relatively, and the initial raw material selection and input costs are relatively high.

Waste plastic pyrolysis machines supplies by DOING

Waste plastic pyrolysis machines supplies by DOING

For investors, choosing between these two products depends on market demand, access to raw materials, and the maturity of the technology. Henan Doing Company has cooperated with customers from 100+ countries and regions all over the world, offering comprehensive waste plastic recycling pyrolysis solutions. If you want to engage in related business, welcome to contact us to get more guidance.

Releate article:

Copyright © 2015-2025.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.