Phone: +86-371-5677-1821

TEL : +86-135-2669-2320

Email: sales@wastetireoil.com

Whatsapp:+86-135-2669-2320

In the world of waste recycling, two key processes are often mentioned: pyrolysis and destructive distillation. While they may seem similar, pyrolysis and destructive distillation are both thermal cracking processes, but they differ in their process conditions, applications, and outcomes. In this article, we'll break down what makes these processes unique.

Pyrolysis is the thermal decomposition of organic materials that are composed of hydrocarbon polymers at elevated temperatures (typically 250–600°C) under anaerobic and oxygen-poor conditions. After pyrolysis, the hydrocarbon polymers breaks down into smaller molecules, gases, and solid residues.

Destructive distillation is the process of heating organic materials in the absence of air to break them down into simpler components, including gases, liquids, and solids.It is a specific type of pyrolysis that often occurs at relatively lower temperatures (200–900°C) and is used to extract useful byproducts.

The main difference between pyrolysis and destructive distillation can be briefly shown in the table below.

| Aspect | Pyrolysis | Destructive distillation |

| Oxygen presence | Absence of oxygen | Absence of air (no oxygen) |

| Temperature range | Typically higher(250-600℃) | Typically lower(200-900℃) (Mainly based on the characteristics of the raw materials) |

| Applications | Waste recycling Resource recovery Fuel production | Mainly used in industries, such as metallurgy and chemical production. |

| Raw material | Tire waste Plastic waste Medical waste Oil sludge Coal tar oil residue Aluminum plastic Multiple hazardous waste | Wood Oil shale Biomass Solid residues (e.g., charcoal) Chemical derivatives(e.g., coal tar for pharmaceuticals) |

| Product | Liquid fuels: pyrolysis oil Solid residues (carbon black) Syn gases Steel wire Aluminum Block | Liquid fuels Coal tar Gases (methane, hydrogen, carbon Monoxide) |

| Product application | Pyrolysis oil is utilized in industrial for fuel. Carbon black used in rubber products manufacturing. Syn gases used as fuel. Steel wire is recycled for metal processing. Aluminum blocks used to produce aluminum alloys or as building materials. | Liquid fuels is used for waterproofing, antiseptics, and adhesives. Coal tar is used for for cooking (e.g., barbecues) and metallurgical processes (e.g., reducing metal ores). Gas is for synthesizing ammonia (fertilizers) or methanol |

| Technical features | Flexible process, temperature, residence time and other parameters can be adjusted according to the raw materials, suitable for small and medium-sized scale production or distributed processing | The process is mature but relatively fixed, usually used in large-scale industrial production (such as coking plants), with large equipment investment. |

If you need to process solid waste, emerging waste such as plastic or rubber biomass and want to obtain multiple products (such as gas, oil, carbon black, etc.), pyrolysis is more suitable. As a leading manufacturer of waste pyrolysis equipment, DOING, offers advanced and efficient waste recycling pyrolysis machines.

DOING waste recycling pyrolysis machine is designed with advanced technology and high - quality materials. It offers excellent performance in handling a wide range of waste materials. With high - efficiency heat transfer systems, our equipment can achieve rapid and complete pyrolysis, maximizing the yield of valuable products like fuel oil and carbon black. And the safety features of DOING waste recycling pyrolysis machine is also remarkable. Equipped with multiple safety protection devices, it ensures stable and safe operation, reducing the risk of accidents. Moreover, our equipment is environmentally friendly. It effectively controls the emission of pollutants during the pyrolysis process, meeting strict environmental protection standards.

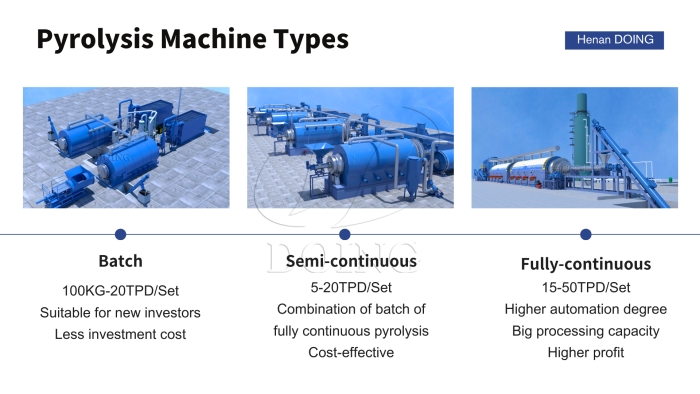

DOING pyrolysis machine types

DOING pyrolysis machine types

In conclusion, understanding the differences between pyrolysis and destructive distillation is essential for choosing the right waste treatment and resource recovery methods. If you would like to learn more about pyrolysis technology, please do not hesitate to contact us.

Releate article:

Copyright © 2015-2025.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.