Phone: +86-371-5677-1821

TEL : +86-135-2669-2320

Email: sales@wastetireoil.com

Whatsapp:+86-135-2669-2320

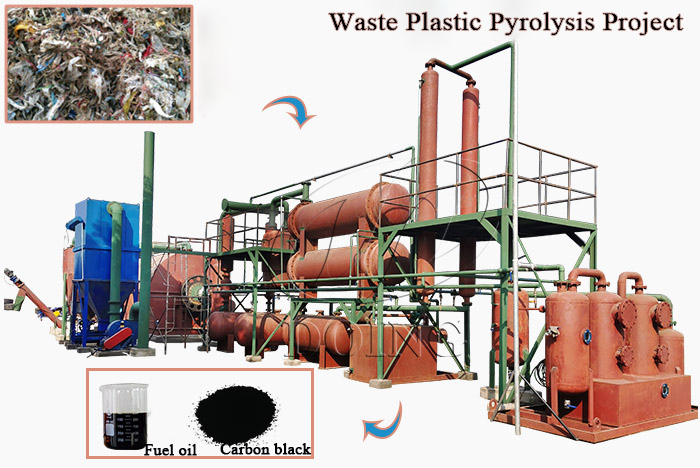

One study states that the world currently consumes 245 million tons of plastic each year, a quarter of which is used for packaging, the most common use of plastic. And only 14 percent of plastic packaging is recycled worldwide, with one-third not collected at all, directly polluting our streets, beaches and oceans. In the past, people usually dispose of waste plastics by direct incineration, but this method causes secondary pollution and is gradually banned in many countries. Therefore, how to deal with waste plastics has become a problem for the whole world. That's why waste plastic pyrolysis plant was created. It can convert waste plastic into fuel oil and carbon black without pollution, meanwhile both fuel oil and carbon black can be used as fuel and have good market value.

Why is waste plastic pyrolysis plant an environmentally friendly way to recycle plastic?

Waste plastic pyrolysis plant

Waste plastic pyrolysis plant

Waste plastic pyrolysis plant is in a fully enclosed form, which allows waste plastic to be pyrolyzed into oil gas and carbon black under high temperature and oxygen-free conditions. Compared with the direct incineration of plastics, it does not allow plastics to come into contact with air and does not produce dioxins, which are a mixture of harmful gases.

The pollution produced by the waste plastic pyrolysis plant is partly non-condensable gas and smoke, which can be treated by equipping environmental protection equipment, and the non-condensable tail gas can be recycled for heating the reactor after purification.

How does a waste plastic pyrolysis plant recycle waste plastics in a friendly way?

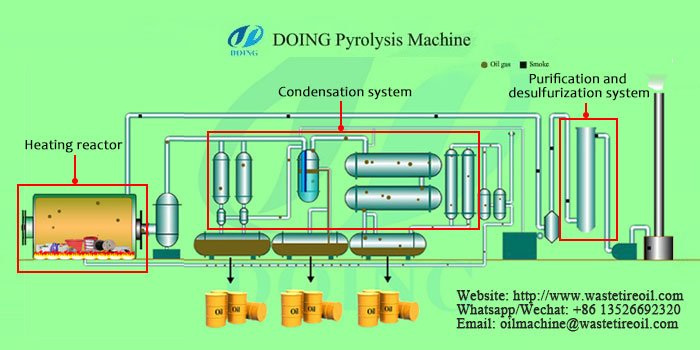

Now, let's take a look at the detailed processing steps of DOING waste plastic pyrolysis plant.

The working flow of Doing waste plastic pyrolysis plant

The working flow of Doing waste plastic pyrolysis plant

First, put waste plastic into the pyrolysis reactor of the waste plastic pyrolysis plant, and then close the inlet and outlet doors tightly to avoid dust or gas leakage to pollute the environment or even bring safety hazards.

Next, heat the pyrolysis reactor with coal, wood, gas, oil or any one of other fuels to convert the waste plastic into oil gas by pyrolysis reaction.

Then, the oil gas will be cooled by the condensation system. After that, the pyrolysis oil gas will be turned into liquid oil and pumped into the tank.

And then, the non-condensable tail gas produced by pyrolyzing process can be purified and recycled for use as fuel to assist heating the pyrolysis reactor, which is environmentally friendly and energy-saving.

At last, the flue gas after combustion of the fuel and tail gas is effectively treated by desulfurization & purification tower to meet the environmental protection standards.

Doing Group has been manufacturing this machine for almost 10 years, so we are constantly upgrading and improving our machine to meet the growing needs of customers. If you have waste plastic and want to get profits from it, welcome to contact us, please leave your contact information below and our professional project manager will contact you ASAP.

Releate article:

Copyright © 2015-2025.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.