Convert the waste oil sludge into oil, water and clean soil with no pollution

Oil sludge is formed in the process of oil exploration, drilling, transportation and tank cleaning which will make the oil mixed with soil, water or other impurities. If the waste oil sludge is not handled properly, it will have a serious impact on the environment and human health. So how can we solve the waste oil sludge?

After years of exploration, we Doing Group have developed the waste oil sludge pyrolysis plant based on the needs of customers and the characteristics of waste oil sludge which can convert the waste oil sludge into crude oil, clean water and soil .

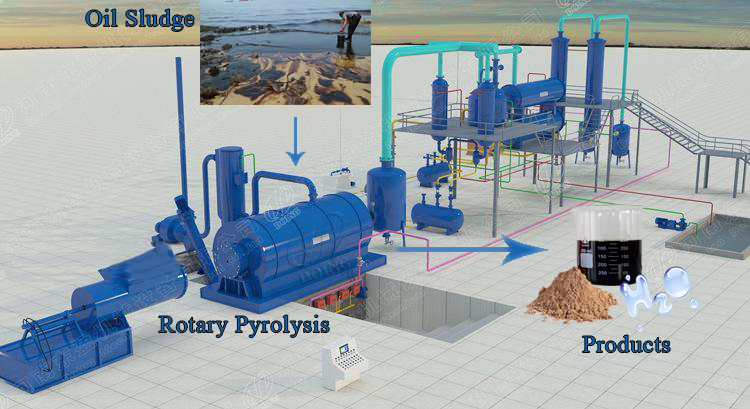

Waste oil sludge pyrolysis plant

The working process of the waste oil sludge pyrolysis plant:

1.Feeding the waste waste oil sludge into pyrolysis reactor through a screw feeder.

2.Heating the pyrolysis reactor in a evenly rotation way to make the waste waste oil sludge produce oil gas.

3.Condensing the oil gas in the cooling system to get liquid oil.

4.Recycling the incondensable gas to heat the pyrolysis reactor through the gas purification system and the water you get can be reused in the cooling system.

5.Slagging the remnant ash into the pit which is under the pyrolysis reactor.

Products of waste oil sludge pyrolysis plant

Our waste oil sludge pyrolysis plant adopt the rotary pyrolysis technology which can effectively recycle and reuse waste oil sludge without secondary pollution. For the waste oil sludge pyrolysisplant, we have different models such as 6t, 8t, 10t etc...

Technical parameter of waste oil sludge pyrolysis plant:

| Items Plants | Waste oil sludge pyrolysis plant |

| Model | DY-1T, DY-6T,DY-8T,DY-10T, DY-12T... |

| Raw material | Waste waste oil sludge |

| Structure form | Horizontal rotation |

| Heating method | Direct heating |

| Operating pressure | Normal pressure |

| Heating material | Fuel oil, LPG, Natural gas, Coal, Wood |

| Average out-put rate | According to the oil content of waste oil sludge |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 14mm/16mm/18mm |

| Mode of cooling | Circulating waster cooling |

| Power in total | 15kw |

| Service life | Average 6 years |

| Land area | 500㎡ |

Advantages of Doing waste oil sludge pyrolysis plant:

1. It can deal with different raw materials, not only all kinds of waste oil sludge, but also the waste rubber tires and plastics;

2.Adopting various environmental protection devices which can make the whole process without pollution;

3. Adopting different safety devices ensure the safety and reliability of the waste oil sludge pyrolysis plant.

4. Effectively solve the coking problem during disposing the waste oil sludge .

waste oil sludge pyrolysis plant projects

Doing waste oil sludge pyrolysis plant has been installed in many countries, such as Venezuela, Saudi Arabia, Iran, Iraq, Kuwait, united Arab emirates, Russia and so on. If you have plenty of waste oil sludge to deal with, Doing waste oil sludge pyrolysis plant will be your best choice, we are looking forward to receiving your consultation.

Waste Plastic Pyrolysis Plant Flow Chart

Converting Plastic Oil to Diesel Flow Chart

Copyright © 2015-2023.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.